The Hidden Backbone of Automation: How Terminal Blocks Keep Control Panels Running

Behind every robotic arm, conveyor belt, or packaging line, there’s a silent network of connections making sure commands are executed exactly as intended.

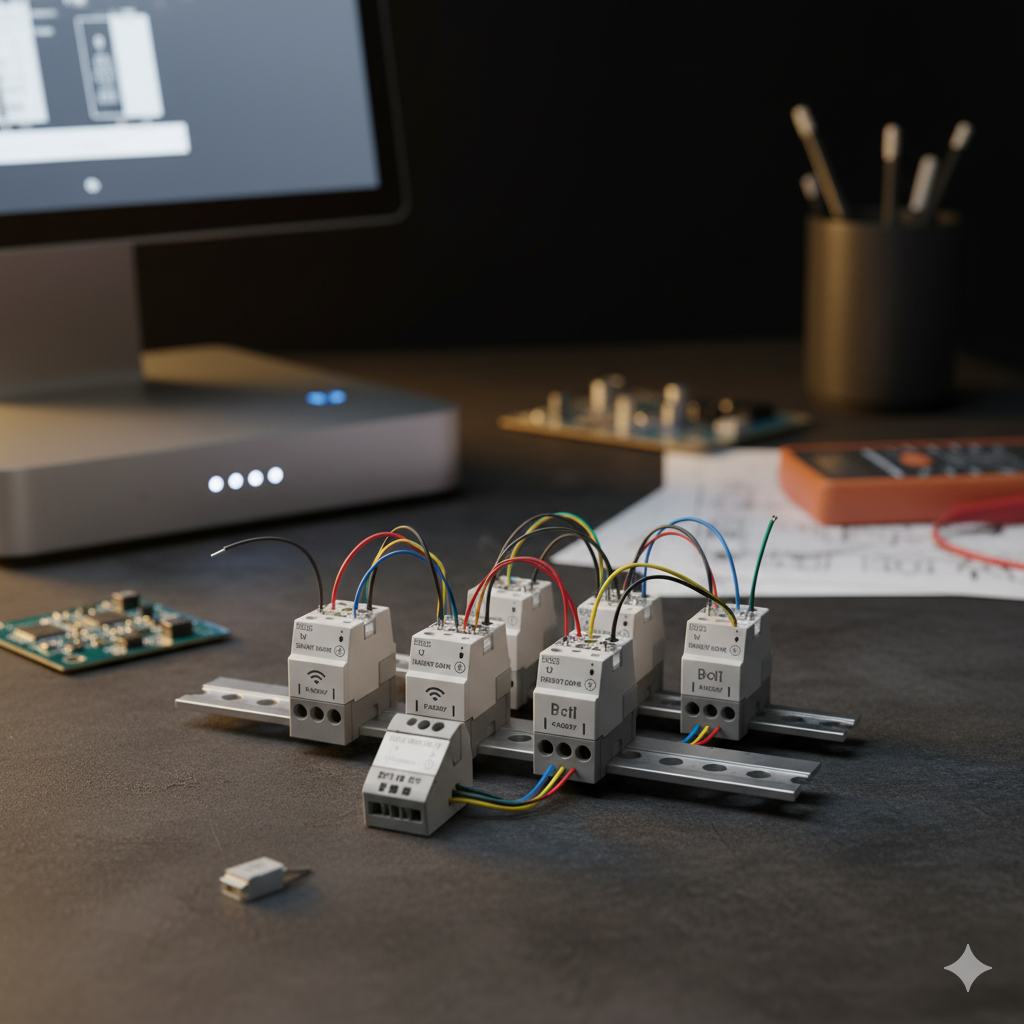

Inside these control cabinets, terminal blocks for automation panels act as the backbone of the system — organizing wiring, isolating signals, and maintaining electrical safety even under nonstop operation.

Without them, automation would be chaos: loose wires, signal interference, and unplanned downtime.

Why Automation Panels Need Engineered Connection Systems

Industrial automation is built around precision and uptime. Every control signal, sensor output, or power feed must travel through reliable connection points.

Unlike simple wiring, automation panels operate in environments with heat, vibration, and electrical noise — conditions that push components to their limits.

That’s why terminal blocks in this field are engineered to handle more than just conductivity:

-

High mechanical strength for 24/7 operation

-

Flame-retardant and heat-resistant materials

-

Secure retention systems that prevent wire loosening under vibration

-

Modular design for quick reconfiguration and expansion

They don’t just connect circuits — they ensure that every electrical path inside a panel remains traceable, safe, and easy to maintain.

How Modern Terminal Blocks Simplify Automation Wiring

Older wiring systems often relied on bulky junctions or crimp connectors, leading to tangled cables and inconsistent performance.

Today’s automation-grade terminal blocks streamline control cabinet design through smarter engineering.

| Feature | Traditional Wiring | Modern Terminal Blocks |

|---|---|---|

| Installation Time | Slow, manual crimping | 40% faster with push-in clamps |

| Maintenance | Difficult tracing | Numbered & color-coded circuits |

| Scalability | Fixed layout | Modular DIN-rail design |

| Signal Integrity | Vulnerable to interference | Shielded and separated paths |

| Safety | Limited flame protection | UL94 V-0 housings and IEC compliance |

The result: faster installation, easier diagnostics, and longer equipment life.

Material Choices that Define Reliability

In industrial environments, every degree of heat and every vibration cycle matters.

That’s why professional manufacturers use materials selected for both electrical stability and mechanical toughness.

| Component | Material | Purpose |

|---|---|---|

| Housing | PA66 UL94 V-0 | Flame-resistant, thermally stable |

| Contacts | Copper alloy (nickel/tin-plated) | High conductivity and corrosion resistance |

| Screws / Clamps | Stainless or zinc-plated steel | Long-term torque retention |

| Mounting Base | Reinforced PC or PA | Shock-resistant structure |

These materials ensure every connection inside the panel stays reliable even in factories with fluctuating temperatures, dust, or mechanical load.

Applications Across the Automation Landscape

| System Type | Wiring Function | Recommended Terminal Type |

|---|---|---|

| PLC Control Panels | Signal input/output routing | Spring clamp terminal, 2.5mm² |

| Motor Control Centers | Power distribution | Screw-type terminal, 25–60A |

| Process Automation Systems | Sensor and actuator wiring | Feed-through modular block |

| Packaging Machinery | Rapid reconfiguration | Pluggable terminal block |

| Smart Factory Panels | Mixed data + power | Hybrid modular connector |

Whether it’s a precision robotic cell or a large-scale conveyor control system, terminal blocks keep the entire electrical ecosystem synchronized.

Practical Guidelines for Automation Engineers

Selecting the right terminal block depends on the type of current, installation layout, and maintenance cycle.

Here’s what engineers should keep in mind when designing or sourcing automation panels:

-

Use spring-cage or push-in terminals for frequent signal rewiring.

-

For high-current loads, select screw-type blocks with torque protection.

-

Maintain minimum 10mm creepage distance between power and control lines.

-

Ensure labeling and testing ports are accessible for maintenance teams.

-

Always verify UL1059 and IEC 60947-7-1 compliance before procurement.

A well-planned connection system doesn’t just meet electrical codes — it saves hours of maintenance and reduces costly downtime.

Common Questions from System Integrators

Q1: Can one panel use both screw and spring terminal blocks?

A: Yes. Many control cabinets combine both for power and signal sections to balance stability and flexibility.

Q2: What’s the typical lifespan of automation terminal blocks?

A: With correct torque and environment protection, they can last over 10 years under continuous duty.

Q3: Are modular blocks suitable for retrofitting old panels?

A: Absolutely. Their DIN-rail design allows easy replacement without major rewiring.

Q4: How do manufacturers test reliability?

A: Through thermal cycling (−40°C to 125°C), vibration tests, and dielectric strength verification.

Designing Automation That Never Stops

In industrial automation, every second of uptime counts. The unsung heroes inside the control cabinet — terminal blocks — ensure that machines communicate, respond, and perform flawlessly day after day.

They bring order to complexity, stability to motion, and reliability to automation.

Zhongbo continues to deliver certified, customizable terminal block systems for automation panels, combining precision molding, UL-certified materials, and global OEM expertise.

For engineering inquiries or product customization, visit our homepage or contact us.