Precision and Safety in Automation: Terminal Blocks for Industrial Control Systems

In modern automation, every control cabinet relies on a stable electrical backbone. Terminal blocks for industrial control systems form the nerve network of machines, connecting sensors, actuators, and PLCs with unmatched precision.

Yet many facilities still struggle with signal loss, wiring complexity, and maintenance downtime caused by poorly matched connection components. Understanding the technology behind professional terminal blocks helps engineers design safer, more scalable control systems.

Engineering Principles Behind Reliable Control Connectivity

Industrial control terminal blocks are purpose-built to manage low-voltage signal transmission and high-current power circuits within the same enclosure.

Their performance depends on three mechanical and electrical principles:

-

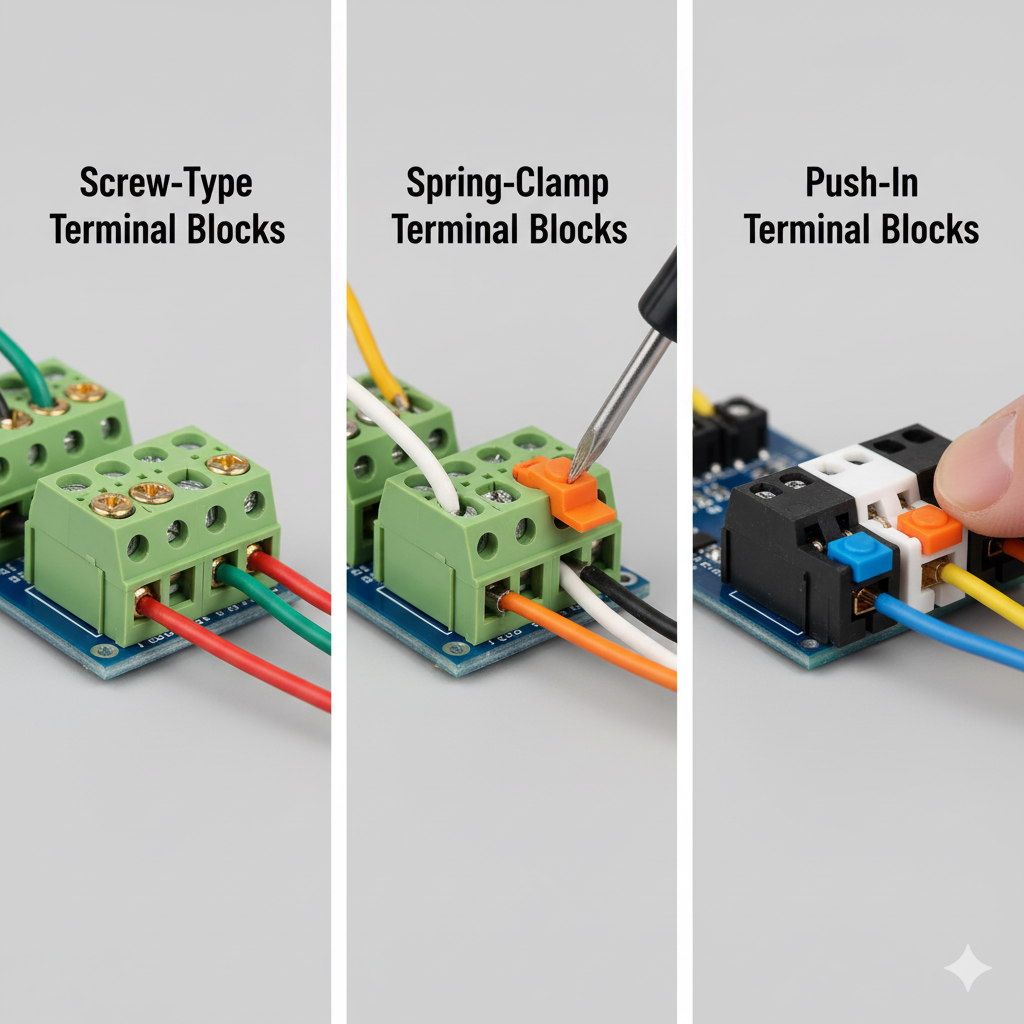

Secure conductor retention through screw or spring-clamp mechanisms

-

Insulation integrity maintained by flame-retardant polymers (PA66 UL94 V-0)

-

Optimized creepage distances preventing short circuits in confined cabinets

By applying these principles, wiring systems meet IEC 60947-7 and UL 1059 standards, ensuring both operator safety and equipment reliability.

Traditional Wiring vs. Modern Modular Terminal Design

| Aspect | Conventional Wiring | Modern Modular Terminal Blocks |

|---|---|---|

| Wiring Time | High due to manual routing | Reduced by up to 40 % via modular assembly |

| Maintenance | Complex tracing | Clear labeling & plug-in modules |

| Reliability | Dependent on cable joints | Stable screw/spring clamp contacts |

| Scalability | Difficult to expand | Stackable rails for future I/O |

| Safety | Limited protection | Certified insulation and flame-retardant materials |

Unlike loose screw terminals or crimp connectors, modular terminal blocks create repeatable torque-controlled connections that remain stable under vibration, temperature cycling, and continuous current flow.

Core Advantages for Industrial Control Applications

-

Signal Integrity and Noise Reduction

Shielded construction minimizes interference between analog / digital channels—vital for PLC and sensor circuits. -

Ease of Maintenance and Wiring Efficiency

Modular labeling and standardized spacing allow technicians to replace or extend circuits without re-routing entire bundles. -

Thermal Stability and Safety Compliance

High-temperature polymers resist deformation at >120 °C, maintaining contact pressure even under load. -

Customization for Control Cabinets

Options include pluggable types, feed-through models, and fuse-integrated terminals—tailored for automation or motor-control systems. -

Reduced Lifecycle Cost

Shorter installation times and fewer wiring failures translate to lower total ownership costs over long operating cycles.

Industrial Environments and Application Scenarios

Terminal blocks are integral to all levels of industrial automation:

| Environment | Function | Typical Terminal Type |

|---|---|---|

| PLC Control Cabinets | I/O signal routing | Spring clamp or pluggable block |

| Motor Control Centers | Power distribution | Screw terminal block 25–60 A |

| Process Automation | Field signal isolation | Barrier or feed-through block |

| HVAC Systems | Multi-signal integration | DIN-rail mount compact module |

| Renewable Energy Controllers | Harsh environment | High-temperature PA66 housing |

Each scenario prioritizes different design parameters—current load, wiring density, vibration endurance—requiring precise component matching.

Engineering Recommendations for System Designers

When selecting terminal blocks for industrial control, engineers should evaluate:

-

Electrical rating: choose ≥2× system current for overload margin

-

Wiring method: spring clamp for frequent service, screw for fixed lines

-

Installation layout: allow 10 mm clearance for heat dissipation

-

Material spec: use UL94 V-0 housing for flammability control

-

Labeling & testing: ensure lot traceability and voltage proof markings

Proper selection aligns mechanical design with maintenance strategy, ensuring consistent plant uptime and faster troubleshooting.

Technical FAQs for Industrial Control Engineers

Q1: How do terminal blocks prevent signal interference in PLC applications?

A: By separating circuits using insulation barriers & metal-shielded designs that reduce crosstalk.

Q2: Can these blocks handle both AC and DC currents?

A: Yes — rated models meet IEC 60947-7 specifications for AC/DC up to 1000 V depending on pitch and conductor size.

Q3: What is the typical maintenance cycle?

A: Visual inspection every six months and torque re-check annually for screw types; spring types require no re-tightening.

Q4: Are pluggable models interchangeable between manufacturers?

A: Not entirely — pitch sizes (3.5 mm, 5.08 mm, 7.62 mm) must match exactly for safe mating.

Elevating Automation Reliability Through Connector Engineering

Industrial automation demands not only high-speed processing but fault-proof connectivity. Advanced terminal blocks empower engineers to achieve modular, maintainable, and safe control architectures that scale with system complexity.

Zhongbo continues to supply certified terminal block systems engineered for control cabinets, PLC modules, and energy automation panels—providing globally trusted reliability with technical customization and fast OEM support.

For specifications, custom configurations, or export cooperation, visit our homepage or contact us.