Global Sourcing for Electrical Integrity: How Panel Mount Terminal Block Suppliers Power Industrial Systems

In industrial automation and power management, the panel mount terminal block stands as a cornerstone of reliable electrical connectivity. It bridges components, secures conductors, and maintains insulation integrity across control cabinets and switchgear systems.

Finding the right panel mount terminal block source goes beyond simple procurement — it defines the stability, service life, and safety performance of the entire electrical installation.

Structural Principles of Panel Mount Terminal Blocks

Panel-mounted terminal blocks differ from PCB types in both mechanical anchoring and load-bearing capacity. They are engineered for external wiring, often installed within control boxes or enclosures, and must handle high mechanical stress, torque, and vibration.

Key structural features include:

-

Mounting base and locking flange for secure panel fixation

-

Screw or spring clamp mechanism ensuring steady conductor retention

-

High creepage distance between conductive paths for voltage insulation

-

Heat-resistant polymer housing (PA66, PC, or PBT) for long-term endurance

-

Nickel-plated brass contacts to minimize oxidation and resistance

These design details enable reliable performance in energy distribution cabinets, HVAC systems, and heavy-duty industrial controllers.

Material Science and Insulation Reliability

Industrial-grade terminal blocks are constantly exposed to high temperatures, humidity, and electrical stress. The housing material and conductor plating play critical roles in ensuring both electrical safety and mechanical integrity.

| Component | Material | Performance Role |

|---|---|---|

| Housing | PA66 UL94 V-0 | Flame retardant, durable insulation |

| Contact | Brass or phosphor bronze | High conductivity, anti-deformation |

| Screw | Carbon steel with zinc plating | High torque retention |

| Mounting Plate | Stainless steel | Vibration resistance and longevity |

Manufacturers typically perform dielectric strength tests at 2.0kV–2.5kV and torque endurance tests to confirm stability under real operating conditions.

Manufacturing Standards and Engineering Validation

To achieve consistent performance, sourcing from certified factories ensures adherence to global quality frameworks.

Advanced manufacturers employ the following processes:

-

Precision Injection Molding – guarantees uniform insulation thickness and tight tolerances.

-

Automatic Screw Assembly – maintains torque accuracy and prevents conductor slippage.

-

Thermal Aging Tests – simulates long-term cabinet heating and current exposure.

-

Optical and Electrical Testing – confirms assembly alignment and continuity for every batch.

Each stage of production integrates traceability systems compliant with ISO9001, ensuring every component meets application-specific requirements.

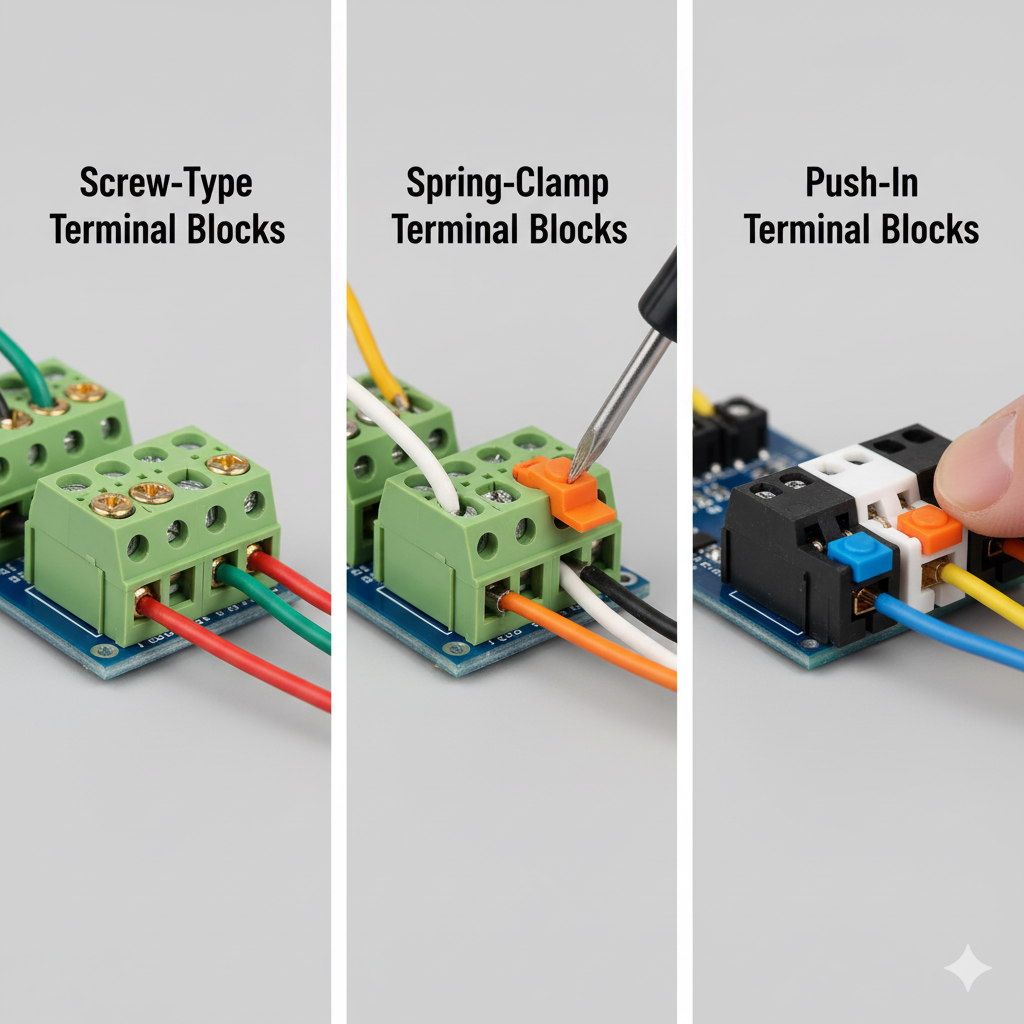

Comparative Insight: Screw vs. Spring Clamp Panel Mount Blocks

| Type | Mechanism | Application | Maintenance |

|---|---|---|---|

| Screw Clamp | Tightened screw compression | High current circuits, motor control | Periodic retorque required |

| Spring Clamp | Elastic retention force | Signal and automation lines | Maintenance-free, faster wiring |

| Hybrid Type | Combined design | Flexible installations | Moderate torque, fast installation |

Choosing the appropriate mechanism depends on conductor type, vibration exposure, and service cycle requirements. Screw clamp models dominate in power-intensive systems, while spring clamp types prevail in compact automation enclosures.

Common Application Environments and Design Considerations

Panel mount terminal blocks must withstand diverse industrial conditions — from high-current busbars to low-voltage control wiring. Below are typical use scenarios and design recommendations:

| Environment | Challenge | Recommended Solution |

|---|---|---|

| Automation Panels | Limited space | Compact modular design with side-entry wiring |

| Power Distribution Units | High load | Brass conductors with enlarged contact area |

| Outdoor Cabinets | Moisture, corrosion | Sealed housing with anti-oxidation plating |

| Marine / Transport Systems | Vibration | Screw-lock terminals and metal mounting base |

| Renewable Energy Systems | Temperature fluctuation | Heat-resistant PBT housing, UL94 V-0 grade |

By adapting mounting orientation, insulation materials, and conductor specifications, engineers can optimize system reliability across environments.

Procurement and Engineering Integration for Global OEMs

Reliable sourcing is not only about cost but also supply chain stability, certification compatibility, and OEM flexibility.

An effective terminal block source should provide:

-

Full compliance with UL1059, IEC60947-7, and RoHS/REACH

-

Customizable colors, pole counts, and mounting orientations

-

Technical documentation (3D models, datasheets, torque specs)

-

Consistent lead time and export packing standards

-

Engineering support for control cabinet design integration

Working with a professional supplier ensures that panel mount terminal blocks meet global standards while aligning with the OEM’s brand and technical parameters.

Guidance for Selecting the Ideal Panel Mount Terminal Block

Selecting the right terminal block begins with understanding electrical and mechanical constraints:

-

Current load: select screw type for ≥20A systems.

-

Space limitation: prefer modular low-profile terminals.

-

Environment exposure: use corrosion-resistant housings.

-

Maintenance cycles: adopt spring clamp systems for quick servicing.

-

OEM customization: ensure access to mold design or engraved branding.

By following these engineering-based selection steps, buyers can reduce downtime, improve wiring efficiency, and extend equipment lifespan.

Advancing Safety Through Material Innovation and Modular Design

Modern sourcing emphasizes compact modularity and material innovation. Factories now integrate automated torque sensors, robotic assembly, and digital inspection to guarantee precision.

As production evolves, the panel mount terminal block is no longer a simple accessory — it has become a critical interface of electrical intelligence, linking safety, flexibility, and maintenance efficiency in industrial design.

Redefining Reliability Through Professional Sourcing Partnerships

A dependable panel mount terminal block source provides more than just components — it delivers engineering stability, traceability, and integration expertise.

With certified manufacturing systems, precision tooling, and customizable designs, Zhongbo continues to support industrial clients with secure, compliant, and globally trusted terminal connection solutions.

For technical consultation or OEM collaboration, please visit our homepage or contact us.