Identifying the Best Chinese Terminal Block Manufacturer for Global Supply Chains

In today’s global manufacturing environment, a terminal block may look like a small component — but sourcing it from the right Chinese manufacturer can make or break your supply chain.

The best Chinese terminal block manufacturer isn’t just about low cost. It’s about quality, certification, consistency, engineering support, and reliable export logistics.

What “Best” Really Means in Terminal Block Manufacturing

-

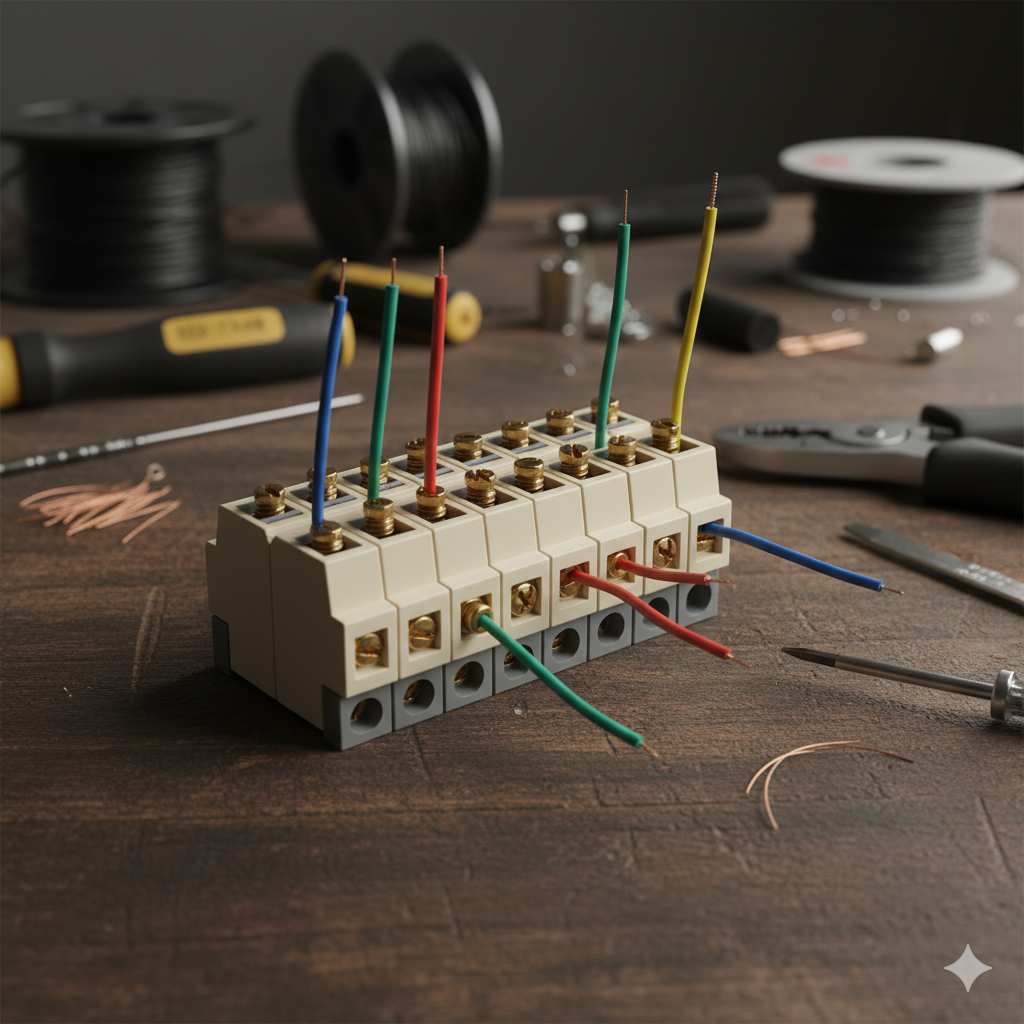

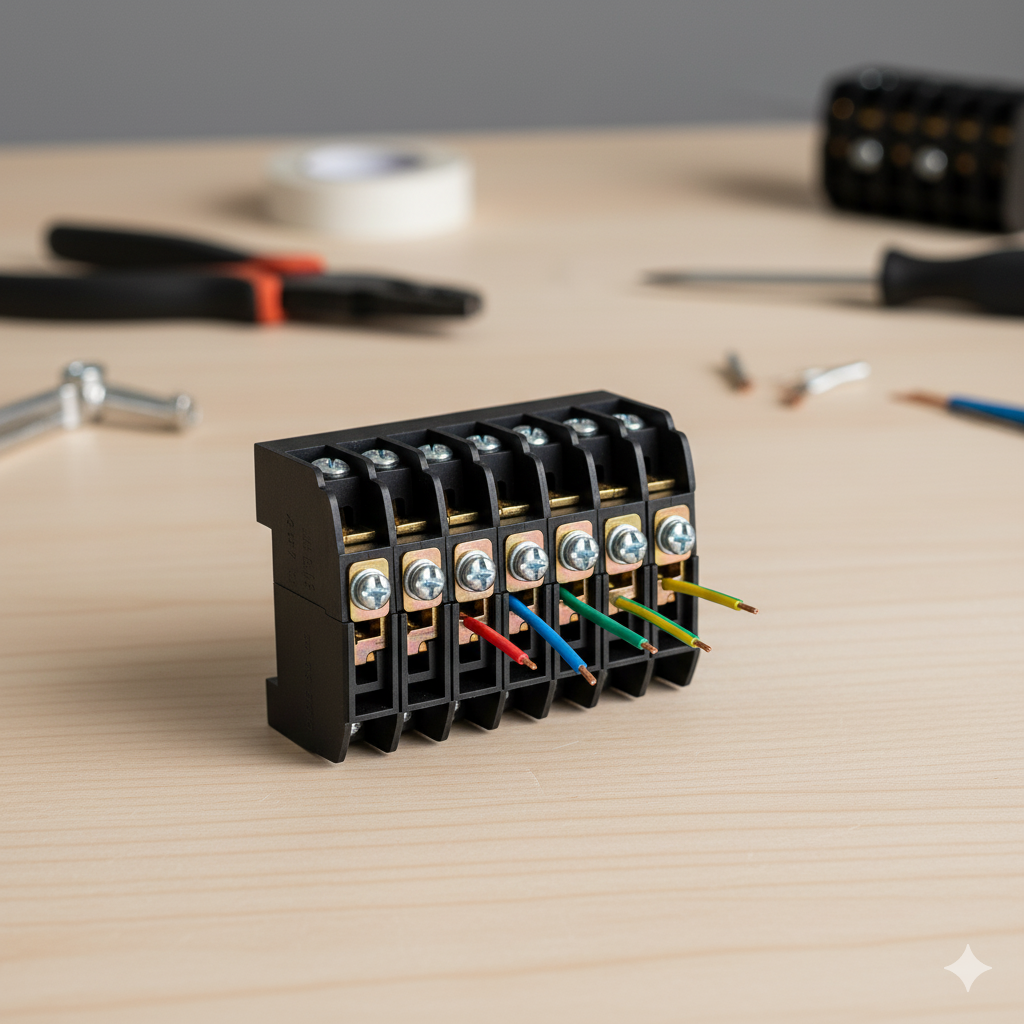

Engineering Capability: A manufacturer that designs molds, controls material sourcing, and manages plating and assembly in-house.

-

Certification & Quality: Factories whose products carry UL, CE, RoHS, and ISO9001/9002 certifications and whose processes honour torque, insulation, temperature-rise testing.

-

Export Readiness: Location near export hubs, experience with international logistics, SKU flexibility, tool-change responsiveness.

-

Customization & OEM Support: Ability to adjust pitch, pole count, housing colour, branding, and support sample-to-mass workflows.

-

Production Scale & Reliability: Automated injection molding, stamping lines, robotic assembly, rigorous inspection and traceability.

How Chinese Manufacturers Rise to Meet Global Standards

Good manufacturers meet international specs not by chance, but by design. Key engineering practices include:

| Engineering Area | Best Practice |

|---|---|

| Housing Material | Use of PA66 or PBT with UL94 V-0 flame-rating to meet fire-safety requirements. |

| Conductor Materials | Brass or copper alloy with tin/nickel plating, to ensure low resistance and corrosion control. |

| Production Automation | CNC injection, stamping, robotic assembly, and on-line inspection (torque, ultrasound, visual). |

| Testing & Certification | 100% dielectric strength test, torque retention test, temperature rise test per IEC/UL protocols. |

| Export Infrastructure | Proximity to ports (e.g., Ningbo, Shanghai), export-compliant packaging, logistics-ready warehousing. |

Such alignment allows Chinese manufacturers to serve industrial automation, renewable energy, HVAC, and global OEMs with confidence.

Why Cost Savings Shouldn’t Be the Only Metric

It’s tempting to judge a manufacturer purely on price. But if cost dominates over quality and consistency, you may face:

-

Product failures in field causing downtime.

-

Rejection in export markets if certification is inadequate.

-

Supply-chain disruptions if tooling or materials are unreliable.

-

Future redesigns or warranty claims that negate initial savings.

Therefore, the “best” Chinese terminal block manufacturer balances competitive cost + global-standard quality + dependable supply.

Selecting the Best Manufacturer: Practical Checklist

When vetting a Chinese terminal block manufacturer, use this checklist:

-

Request certification documents (UL1059, IEC60947, CE, RoHS) and verify authenticity.

-

Visit the factory (or request video/virtual tour) to inspect molding, plating, assembly lines.

-

Ask for sample testing results (torque, insulation, temperature rise).

-

Confirm tooling and customization capability (mold ownership, pitch changes, OEM marking).

-

Assess export logistics and delivery performance (port proximity, lead-time history).

-

Check after-sales support and traceability, such as lot number systems and corrective-action records.

Using a structured evaluation avoids surprises and ensures your component procurement supports your product roadmap, not conflicts with it.

Finding Your Ideal Manufacturing Partner in China

In sum, the best Chinese terminal block manufacturer is the one that delivers engineering integrity, compliance, supply chain reliability, and cost efficiency — all tailored to your global market needs.

If you’re seeking a partner that meets these criteria, consider Zhongbo — a factory providing certified, export-ready terminal blocks with customization support and global logistics integration.

For inquiries, visit our homepage or contact us.