Building Reliability from the Ground Up: Inside an OEM Terminal Block Manufacturer’s Process

When Generic Components Limit System Reliability

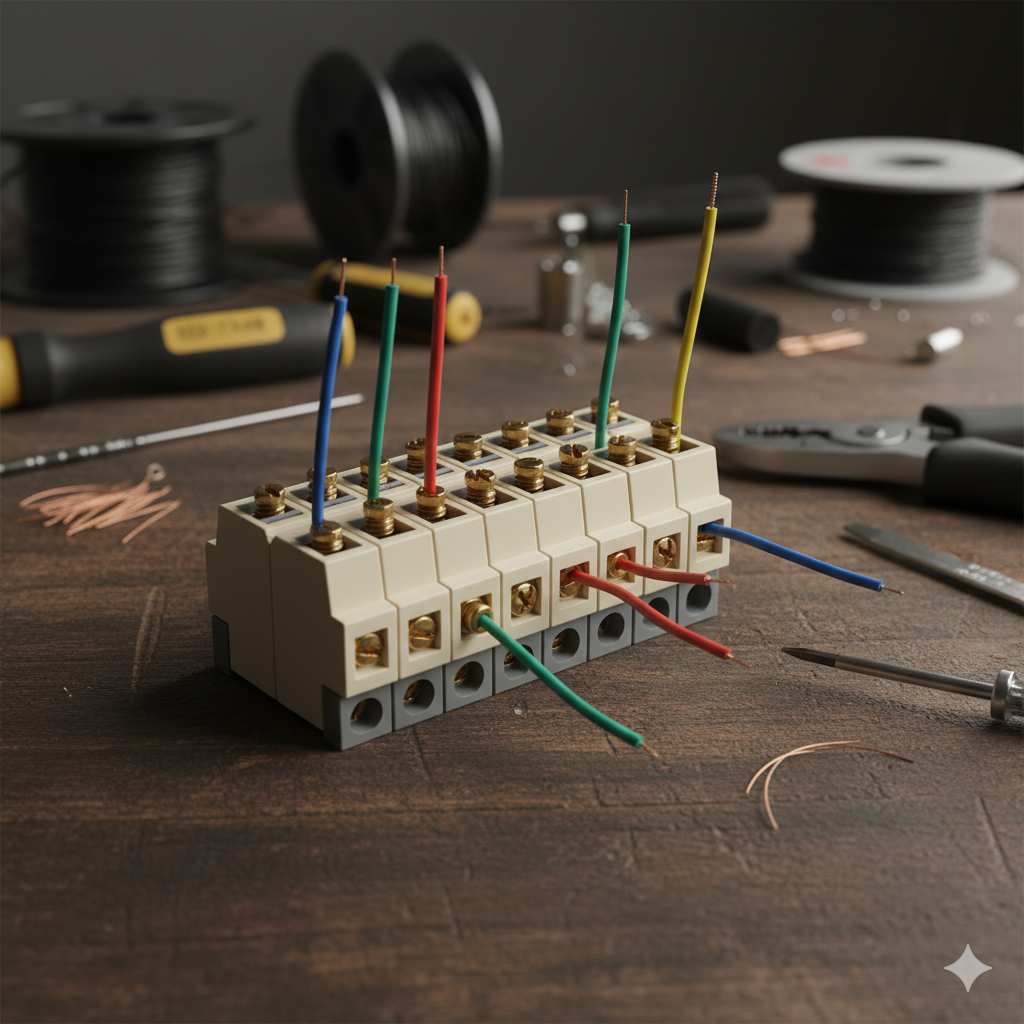

In every control panel, solar inverter, or industrial drive, the electrical connection is the invisible backbone.

Yet many OEM engineers face the same issue—off-the-shelf terminal blocks rarely fit system-specific needs. The current ratings mismatch, the mounting holes don’t align with the enclosure, and certifications vary from region to region.

Every minor modification, from spacing to insulation distance, ripples into production delays, compliance headaches, or warranty claims.

For system integrators or equipment builders, these mismatches aren’t design inconveniences—they’re recurring liabilities.

This is where working with an OEM terminal block manufacturer changes the equation: turning the terminal block from a generic accessory into a precision-engineered interface built for your exact system architecture.

Designing Connections That Serve the System

In OEM manufacturing, customization follows logic, not luxury.

Each terminal block design begins with a system’s electrical and mechanical DNA:

-

Rated Load Analysis: Current, surge, and voltage stress define the copper mass and contact geometry.

-

Thermal Management: High-load points demand optimized heat dissipation paths and high-CTI housing materials.

-

Mechanical Fit: Mounting orientation, screw angles, or pluggable interfaces must adapt to cabinet ergonomics.

-

Certifications and Standards: UL 1059, IEC 60947-7-1, and RoHS compliance must align with export market expectations.

A mature OEM manufacturer uses DFM (Design for Manufacturability) and FMEA (Failure Mode and Effects Analysis) to make sure what’s drawn in CAD can be molded, assembled, and certified—without compromising reliability.

Standard vs. OEM Manufacturing: A Practical Comparison

| Criteria | Standard Components | OEM Terminal Block Manufacturing |

|---|---|---|

| Design Basis | Generic | Tailored to system specs |

| Electrical Range | Fixed SKUs | Tuned to actual load profile |

| Mounting Fit | Often adapted manually | Engineered to panel or PCB layout |

| Testing & Validation | Basic inspection | Full electrical & mechanical validation |

| Certification | Limited regions | Extended UL/CE/CCC coverage |

| Scalability | Volume-driven | Modular & project-driven |

The contrast isn’t simply about customization—it’s about control.

An OEM partnership provides the ability to engineer certainty instead of accepting compromises.

The Solution: Process-Driven Custom Manufacturing

A true OEM terminal block manufacturer integrates tooling, molding, and assembly into a unified process.

Customization no longer means starting from zero; it’s parametric engineering, supported by modular tooling and precision process control.

-

Modular Tool Design: Shared inserts enable dozens of pitch and pole configurations.

-

Advanced Materials: Glass-filled PA66 or PBT housings deliver flame resistance and mechanical strength.

-

Automated Stamping: High-speed precision stamping ensures consistent torque and low resistance.

-

Quality Assurance: Automated vision inspection, pull-out force testing, and hipot verification ensure zero-defect delivery.

-

Certification Integration: Each variant inherits parent certification data, reducing the time from prototype to market.

This hybrid model—custom geometry, standardized production—allows global OEMs to receive tailored products without trade-offs in scalability or compliance.

Key Advantages of Working with an OEM Partner

-

Precision Without Rework

Every terminal block fits from the first assembly, minimizing layout revisions. -

Reduced Wiring Time

Optimized conductor entry angles and pre-labeled plug-ins accelerate installation. -

Thermal Stability

High-conductivity copper alloys and balanced housing geometry reduce hot spots in continuous operation. -

Regulatory Consistency

A single design certified for multiple regions avoids redundant approvals. -

Scalable Supply Chain

From pilot builds to volume production, modular tooling supports consistent output.

In essence, OEM collaboration transforms terminal blocks from consumable parts into strategic components of electrical design.

Application Scenarios: Customization in Action

-

Automation and Robotics

Multi-level spring terminals reduce space in dense control cabinets. -

Renewable Energy

High-voltage terminal blocks with CTI ≥ 600 prevent arcing in 1000V DC circuits. -

HVAC Systems

Color-coded barrier terminals simplify field wiring and retrofits. -

Transportation Electronics

Anti-vibration screws and nickel-plated contacts ensure long-term stability. -

PCB-based Power Modules

3.81mm to 7.62mm pitch connectors integrate directly with driver boards.

Every use case illustrates one fact: OEM engineering builds precision that fits the mission, not the catalog.

Selection Advice: Matching Terminal Blocks to Application Demands

| Environment | Preferred Connection Type | Design Focus |

|---|---|---|

| High Current Loads | Screw clamp | Increased conductor cross-section |

| Compact Panels | Push-in or multi-tier | Space optimization |

| Frequent Maintenance | Pluggable connectors | Quick replacement |

| Vibration-Prone Systems | Spring clamp | Self-locking mechanism |

| Outdoor or High-Temp | PA66/PBT materials | UV and heat resistance |

Selecting the right OEM partner means looking beyond price—verify their engineering documentation, test reports, and global logistics capability.

Frequently Asked Questions

Q1: What is the MOQ for OEM terminal blocks?

Most modular OEM factories can begin custom production at 1,000–2,000 pieces per variant.

Q2: How does certification work for new models?

Existing UL/CE certificates are extended using component-level test data—reducing full test cycles by 50%.

Q3: Can OEM manufacturers handle mixed connection types?

Yes, hybrid designs (push-in + screw) are widely adopted in control and power modules.

Q4: What’s the typical lead time?

3–5 weeks for prototype validation, then steady production through modular molds.

From Engineering Drawings to Long-Term Value

Partnering with an OEM terminal block manufacturer is not just a procurement choice—it’s a strategic investment in precision, reliability, and compliance.

Through modular design, certified processes, and integrated testing, OEM manufacturers turn connection hardware into durable, repeatable engineering assets.

To explore tailored solutions for your next control or energy project, visit our homepage or contact us via Contact Us.

Zhongbo combines technical depth and manufacturing discipline to ensure every terminal block you use is not only connected—but engineered to last.