Precision Through Personalization: How Customized Terminal Block Factories Redefine Electrical Design

In the realm of electrical and industrial control systems, precision isn’t optional—it’s survival.

Yet the reality on most factory floors tells another story: engineers forced to bend their designs around catalog limitations, retrofitting enclosures, or modifying printed circuit boards to match the “closest available” terminal block.

Each workaround introduces risk. Too little creepage distance invites arc faults. Oversized housings waste panel space. A mismatch in screw torque can lead to contact fatigue or thermal rise.

The problem isn’t the component—it’s the rigidity of standardization.

And that’s where a customized terminal block factory becomes more than a supplier; it becomes a design collaborator.

The Engineering Logic Behind Customization

Customization, at its best, is not cosmetic—it’s structural.

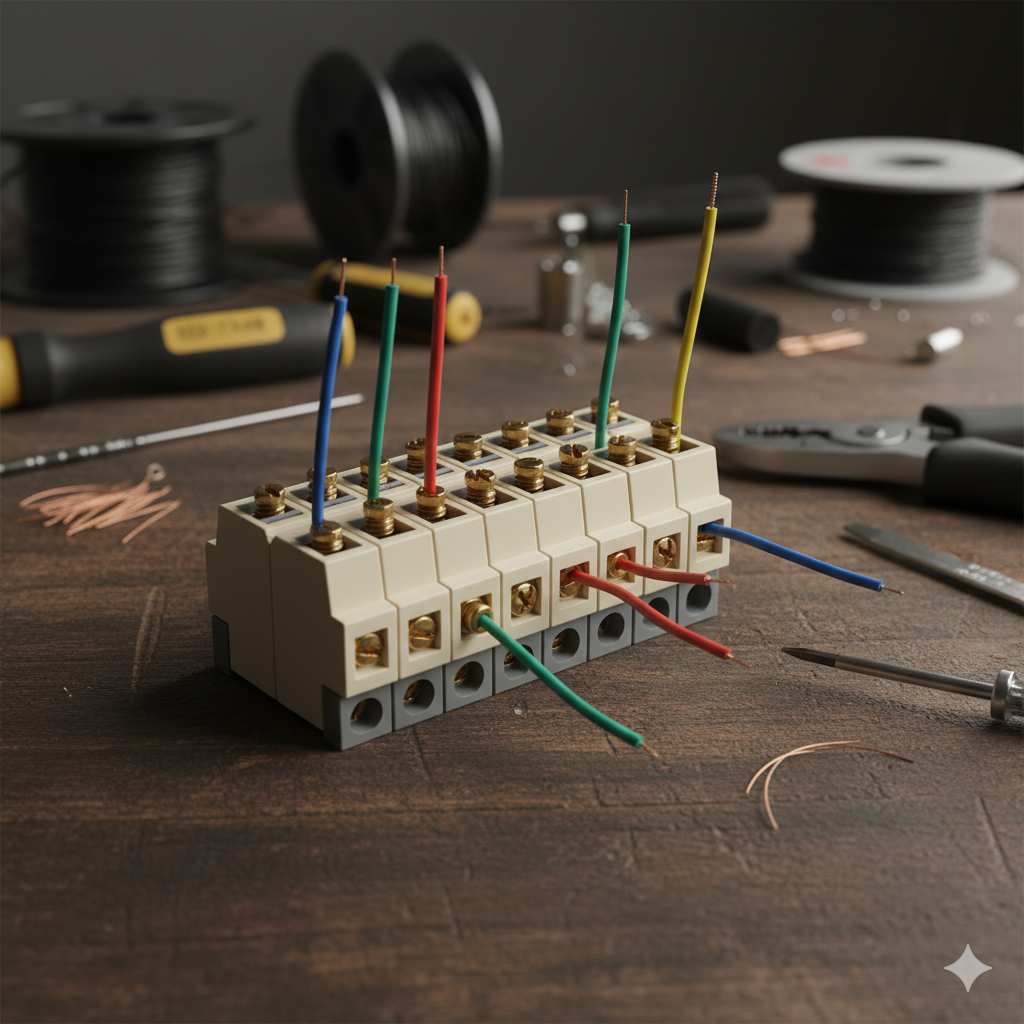

In a modern factory specializing in tailored terminal blocks, design begins with the current path rather than the catalog number. Engineers deconstruct the electrical profile—rated current, surge behavior, dielectric strength—and rebuild geometry from first principles.

Then comes the mechanical symphony: the alignment of wire entry angles, screw access zones, PCB spacing, and torque vectors.

Material scientists enter the picture next—balancing PA66 for heat endurance, PBT for rigidity, and LCP for high-temperature creep resistance.

Every decision intertwines physics, manufacturability, and certification logic.

This fusion of disciplines allows such factories to deliver blocks that fit perfectly, wire faster, and pass global standards with fewer iterations.

Standard vs. Custom: Two Philosophies, Two Outcomes

| Feature | Standard Terminal Block | Customized Terminal Block |

|---|---|---|

| Design Basis | Generic market demand | Application-specific configuration |

| Electrical Range | Fixed | Tuned to load & insulation needs |

| Fit & Form | Limited mounting options | Exact fit for PCB or rail |

| Wiring Efficiency | Average | Up to 40% faster |

| Certification | Generic UL/CE | Matched to export region |

| Lifecycle Cost | Higher (due to rework) | Lower (optimized integration) |

The contrast is not about “price versus performance.”

It’s about philosophy: mass conformity versus precision alignment.

A customized approach eliminates the small inefficiencies that compound into costly errors—mis-torqued screws, excess heat, and maintenance rework.

The Solution: Modular Custom Engineering

Factories leading the customization wave rely on modular innovation.

Instead of retooling from scratch for every project, they employ parametric mold inserts, shared metal cores, and digital CAD templates that allow thousands of variations—pitches from 3.5 mm to 10.16 mm, angles from 90° to 180°, or hybrid push-in and screw combinations—all built on the same production framework.

Automated assembly ensures torque accuracy; 3D coordinate measurement systems verify every cavity.

Each batch undergoes UL 1059 dielectric testing, IEC 60947-7-1 torque validation, and insulation resistance checks.

The result?

Customization that behaves like mass production—repeatable, certifiable, scalable.

The Competitive Edge: Why Customization Wins

-

Precision Integration – Every millimeter counts. Tailored spacing prevents wire stress and improves thermal dissipation.

-

Reduced Wiring Time – Push-in or spring clamp models slash installation time by a third, enabling faster commissioning.

-

Optimized Reliability – Contact geometry fine-tuned to minimize vibration-induced loosening, ideal for machinery and transportation.

-

Regulatory Assurance – Certification profiles built per market: UL for the U.S., CE for Europe, CCC for Asia—no retrofit delays.

-

Lower Total Cost of Ownership – Small design accuracy multiplies into long-term savings: fewer errors, less downtime, and lower maintenance overhead.

Customization isn’t more expensive—it’s more intelligent.

Industry Applications: Where Precision Meets Purpose

-

Industrial Automation Panels – Multi-layer compact blocks free up rail space while preserving accessibility.

-

Renewable Energy Systems – 1000 V DC models with high CTI ratings sustain heavy loads under UV and dust exposure.

-

HVAC Controls – Color-coded plug-ins make field servicing foolproof for installers.

-

Rail & EV Power – Screw-clamp hybrids absorb vibration without loosening, maintaining stable current flow.

-

LED Drivers & Lighting Systems – Low-profile PCB blocks with halogen-free housing reduce thermal fatigue and improve safety.

Every environment defines its own stress points; customized designs simply engineer them out.

Selection Guide: Matching Design to Environment

| Environment | Recommended Type | Design Focus |

|---|---|---|

| High Vibration | Spring clamp / Push-in | Self-locking contacts |

| High Current | Screw clamp | Copper mass & heat path |

| Compact Panels | Multi-tier block | Vertical access & labeling |

| Outdoor Use | PA66/PBT | UV + moisture resistance |

| Frequent Servicing | Pluggable type | Quick replacement & color coding |

Selecting a partner goes beyond picking a model—it means evaluating their engineering literacy: Do they model current density? Validate torque curves? Provide 3D drawings for PCB layout?

Those answers determine whether customization delivers its promise.

Common Questions

Q1: Isn’t customization slower than buying standard parts?

Initial design may add one to two weeks, but once tooling stabilizes, repeat runs flow like catalog products—with fewer reworks.

Q2: What about certifications?

Most factories extend existing UL/IEC files. Only major structural changes require full retesting, significantly cutting time to approval.

Q3: Can small batches be customized?

Yes. Modular tooling allows cost-effective MOQs starting at 1 000 pcs.

Q4: Are mixed connection types possible?

Absolutely. It’s common to integrate push-in for signals and screw clamps for power in a single housing.

Engineering Partnership: From Blueprint to Long-Term Performance

Customization is not an indulgence—it’s a form of engineering precision.

Every conductor, screw, and insulator has a purpose; every adjustment, a measurable effect.

By partnering with a customized terminal block factory, you’re not just buying hardware—you’re embedding process intelligence into your product.

To discuss how tailored designs can elevate your system performance, visit our homepage or reach out via Contact Us.

Zhongbo stands behind every design with the discipline of precision manufacturing, ensuring each terminal block becomes a lasting connection—literally and strategically.