Precision in Compact Wiring: Inside DG300 PCB Connector Manufacturing in China

Modern automation and power control systems demand electrical components that are compact yet mechanically stable. The DG300 PCB connector—known for its 3.81mm pitch and precision plug-in structure—has become a cornerstone of low-voltage electrical interface design.

As global demand for modular PCB connectors grows, China’s DG300 manufacturing ecosystem has evolved to deliver high precision, consistent quality, and reliable compliance with international standards.

Engineering Logic of the DG300 Series

The DG300 series represents the new generation of pluggable PCB connectors that combine miniaturization with electrical integrity. Its structural and functional design solves several critical challenges in dense control systems:

-

3.81mm Pitch Compactness: Enables tight PCB layouts without compromising insulation distance.

-

Pluggable Male-Female Interface: Facilitates quick assembly and maintenance.

-

High Contact Precision: Ensures stable current flow with low resistance.

-

Mechanical Locking System: Prevents accidental unplugging under vibration.

-

Rated Voltage and Current: Typically supports 300V / 8A, ideal for signal and low-power applications.

These design principles make DG300 connectors essential in control boards, sensors, and lighting systems where space, serviceability, and stability converge.

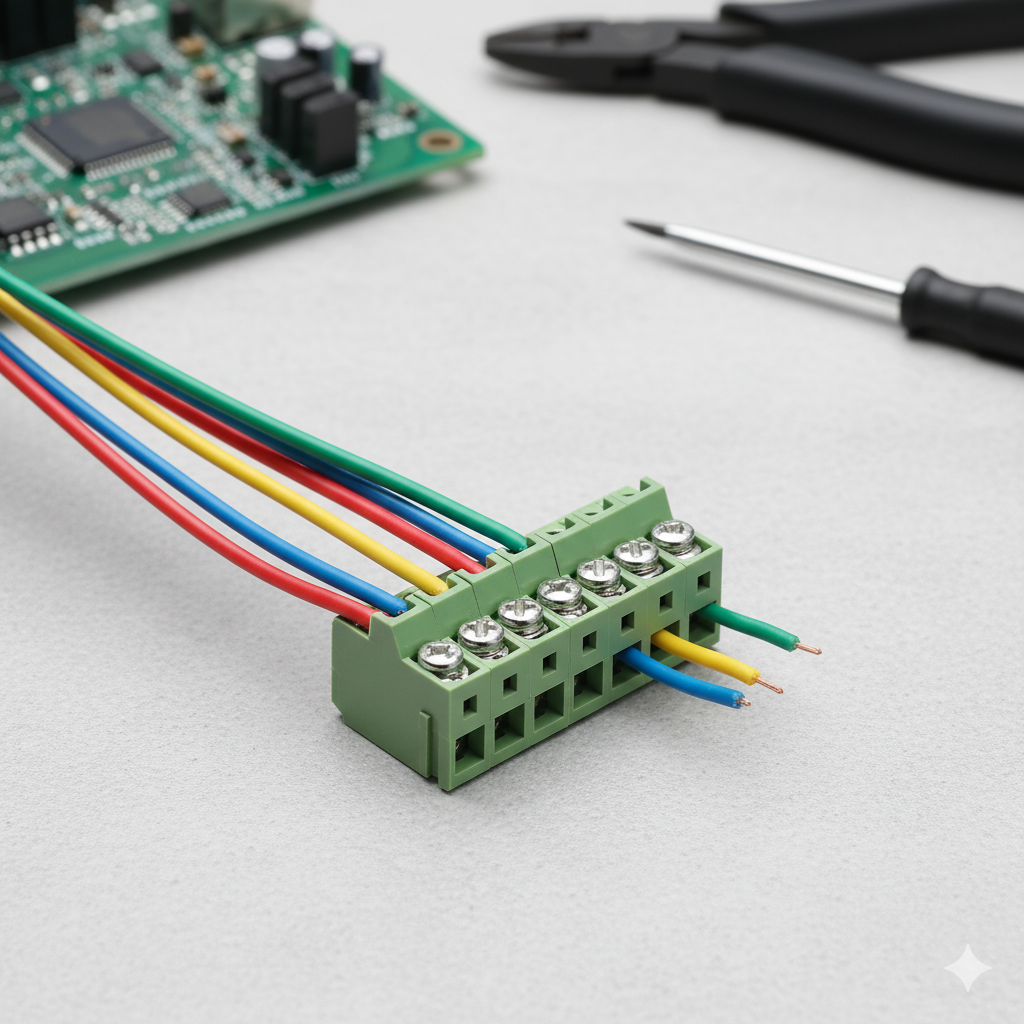

Material Composition and Electrical Integrity

The performance of a DG300 connector depends on its material selection and structural precision. Every part must maintain tight tolerance, ensuring consistent electrical performance over time.

| Component | Material | Function |

|---|---|---|

| Housing | PA66 UL94 V-0 | Flame retardant, heat-resistant insulation |

| Contacts | Brass with tin plating | Low resistance and corrosion resistance |

| Screws | M2.5 carbon steel | Stable torque retention |

| Header | Reinforced glass fiber PA | Dimensional stability for PCB fit |

Each contact is plated to a thickness of ≥2μm, optimizing conductivity and surface resistance. Combined with precision-molded housings, the DG300 can maintain contact resistance below 20 mΩ and withstand 500V dielectric voltage tests across production batches.

Manufacturing Process: Precision and Consistency

China’s DG300 connector factories integrate advanced manufacturing processes that combine automation and inspection at every stage:

-

High-Pressure Injection Molding – Ensures uniform insulation thickness and zero air inclusions.

-

CNC Machining for Molds – Guarantees consistent terminal geometry across high-volume production.

-

Robotic Plating and Cleaning – Provides stable adhesion and corrosion resistance.

-

Torque Calibration Systems – Validates screw force uniformity within ±5% of nominal values.

-

Electrical and Mechanical Testing – Includes dielectric, pull-force, and heat-cycle validation per UL1059.

These precision-driven workflows ensure each DG300 connector performs identically, meeting both export and domestic compliance requirements.

Compliance and International Standards

To support export-ready reliability, top-tier Chinese DG300 manufacturers integrate multi-standard compliance systems directly into production:

-

UL1059 – Governs terminal block insulation and flammability for industrial systems.

-

IEC60947-7-1 – Defines electrical connection performance for low-voltage equipment.

-

RoHS & REACH – Ensures material environmental compliance.

-

ISO9001:2015 – Confirms quality management traceability across manufacturing stages.

This level of compliance ensures DG300 connectors can be directly used in UL- and CE-certified equipment for automation, energy control, and PCB-mounted applications.

Comparative Analysis: DG300 vs. DG301 vs. DG500

| Specification | DG300 | DG301 | DG500 |

|---|---|---|---|

| Pitch | 3.81mm | 5.08mm | 5.0mm |

| Rated Voltage | 300V | 300V | 600V |

| Rated Current | 8A | 15A | 24A |

| Size Density | High | Moderate | Low |

| Typical Use | Compact PCB control | Power PCB wiring | Industrial distribution panels |

The DG300 offers the best ratio of density to current capacity, making it the go-to solution for engineers designing compact automation modules and control PCBs.

Application Insights Across Industrial Environments

DG300 connectors are used wherever compactness and modularity are essential:

-

Industrial Automation: PLC control boards and distributed I/O modules.

-

Building Management Systems: HVAC and lighting control wiring.

-

Instrumentation: Low-voltage signal interfaces and monitoring circuits.

-

Telecommunication Devices: Reliable board-to-wire connections.

-

Renewable Energy Control Boards: Compact wiring in DC power controllers.

In each application, the DG300’s modular design simplifies installation while maintaining high mechanical integrity and dielectric spacing.

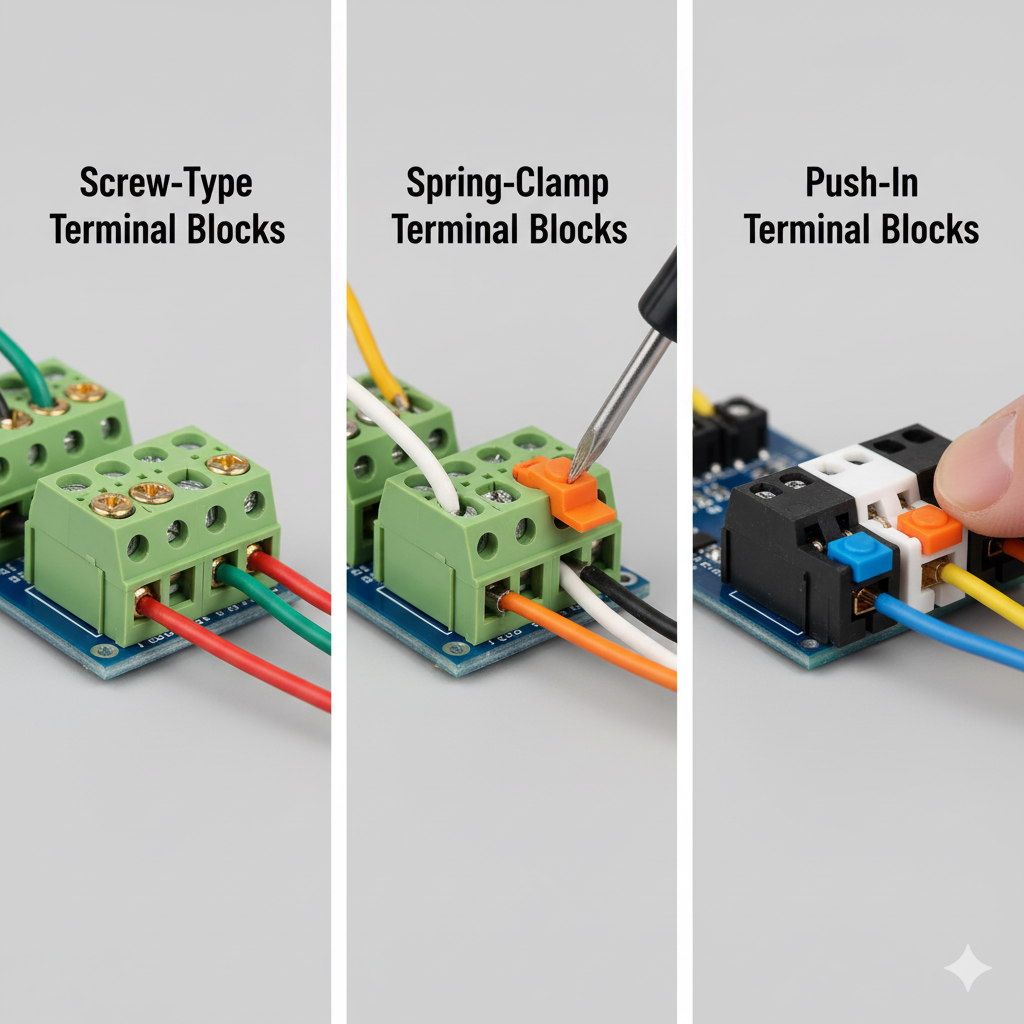

Configuration Recommendations Based on Environment

The choice of DG300 connector design should match the mechanical and electrical environment of its application.

| Environment | Primary Challenge | Recommended Configuration |

|---|---|---|

| High-Vibration Equipment | Loosening and fatigue | Lock-screw variant with serrated washers |

| High-Temperature PCB Boards | Continuous load cycles | Nickel-plated contacts with PA66 housing |

| Compact Control Panels | Space limitation | Vertical entry type, multi-pole modular design |

| Outdoor or Corrosive Conditions | Oxidation and moisture | Sealed plating with reinforced resin |

| OEM Integration | Brand customization | Custom mold logo, modular pole configuration |

Procurement teams should verify UL file numbers, plating documentation, and dimensional drawings to ensure compatibility with OEM PCB layouts.

A manufacturer with in-house tooling, plating, and assembly can maintain consistency across long production runs—critical for global distribution.

Advancing Compact Electrical Interfaces Through Process Intelligence

The evolution of DG300 PCB connectors reflects the global trend toward smaller, denser, and smarter interconnects.

Factories are adopting automated optical inspection (AOI), AI-driven plating control, and digital torque analytics to eliminate micro-defects and improve process repeatability.

This data-centric approach ensures that every connector produced meets both mechanical precision and electrical reliability, ready for integration into next-generation automation systems.

Building Reliability for the Global PCB Ecosystem

The DG300 PCB connector demonstrates how compact mechanical design, robust materials, and process automation together define a new benchmark for reliable connectivity.

Through precision tooling, strict certification, and export-ready consistency, these connectors have become integral to modern electrical engineering.

Zhongbo continues to advance DG300 connector manufacturing in China by implementing UL-compliant materials, intelligent inspection systems, and full OEM customization—empowering engineers and distributors worldwide to build safer and more efficient electrical networks.

To explore product specifications, customization options, or bulk procurement inquiries, please visit our homepage or contact us.