Exporting Reliability: How 15EDGK Terminal Blocks Redefine Global Electrical Standards

In global industrial automation, a single terminal connection often determines whether a system runs efficiently—or fails unexpectedly. The 15EDGK terminal block, recognized for its secure pluggable interface and robust insulation, represents a new generation of modular electrical connectors built for export-grade reliability.

This article explores how 15EDGK terminal block export manufacturing combines structural precision, international certification, and mechanical endurance to serve global OEMs and panel builders.

Engineering Principles Behind the 15EDGK Series

The 15EDGK series is designed to solve one of the biggest challenges in industrial wiring: balancing compact PCB integration with high mechanical retention and electrical safety.

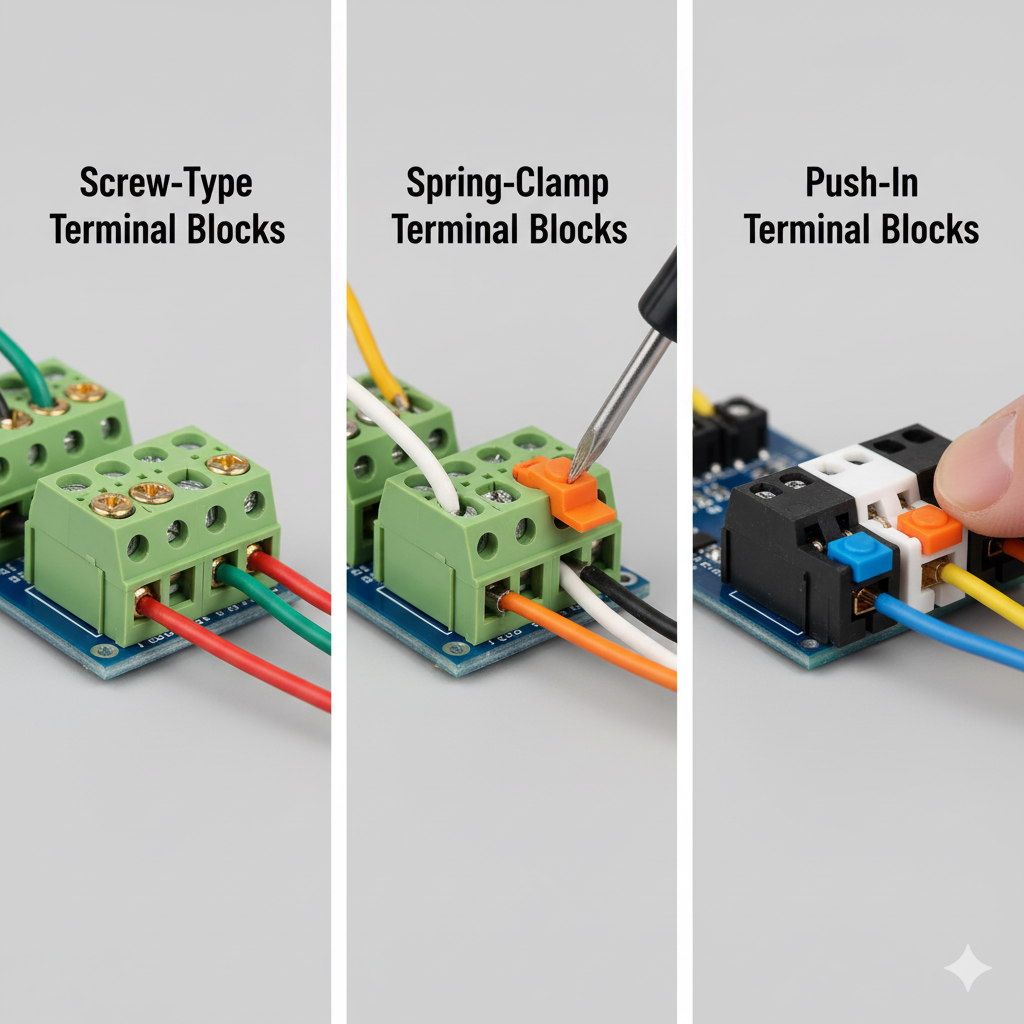

Its design follows a two-part pluggable structure—a male header and a female socket—with the following advantages:

-

Pitch Range: 5.08mm standard, supporting 300V–400V applications.

-

Secure Plug-Lock Mechanism: Prevents accidental disconnection under vibration.

-

Screw and Spring Hybrid Clamping: Ensures high contact pressure for stable conductivity.

-

Modular Design: Allows multi-pole customization from 2 to 24 positions.

-

Temperature Endurance: Operates continuously up to 120°C.

These characteristics make 15EDGK blocks ideal for automation, energy conversion, and control systems that demand modular assembly and frequent maintenance.

Material Composition and Electrical Durability

High reliability begins with precise material selection. Each 15EDGK unit combines UL-rated polymers and conductive alloys engineered to withstand current surges and thermal cycles.

| Component | Material | Engineering Function |

|---|---|---|

| Housing | PA66 UL94 V-0 | Flame retardant, high temperature stability |

| Terminal | Brass (tin/nickel plated) | Conductivity and oxidation resistance |

| Screws | Carbon steel with anti-vibration coating | Secure clamping torque |

| Header | Glass fiber reinforced resin | Mechanical rigidity and alignment precision |

Electrical testing confirms contact resistance ≤ 10mΩ, dielectric strength ≥ 2.5kV, and mechanical endurance beyond 100 plug/unplug cycles—meeting export specifications across EU and North American markets.

Manufacturing and Quality Assurance

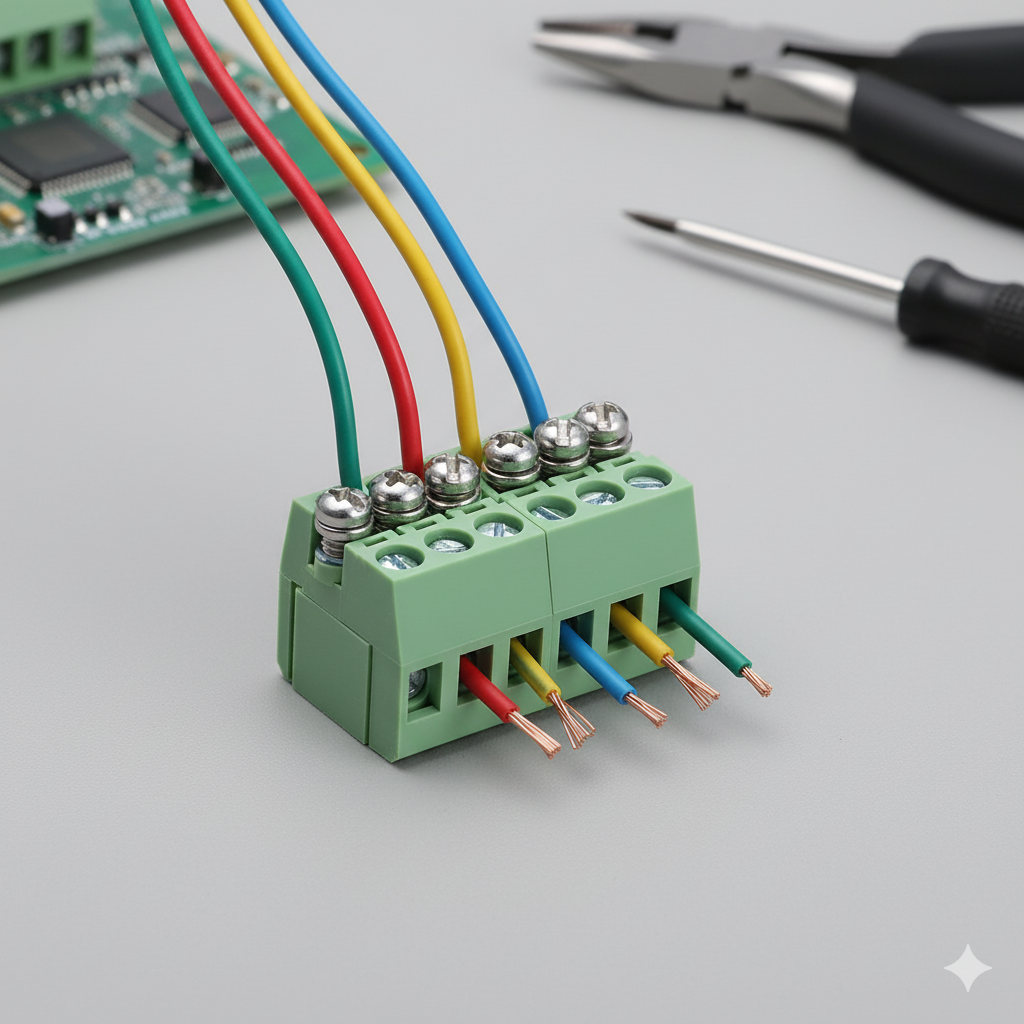

A true export-grade 15EDGK terminal block requires manufacturing precision at every stage:

-

High-Precision Injection Molding: Guarantees uniform barrier walls and consistent insulation thickness.

-

Robotic Assembly: Aligns contacts and screws within ±0.02mm, reducing variation across mass production.

-

Automated Plating Control: Maintains consistent tin/nickel thickness to prevent conductivity drift.

-

Torque Validation Systems: Ensures screw locking force stability across all poles.

-

High-Voltage Testing: Verifies insulation resistance and dielectric breakdown limits for each batch.

The combination of automation + data traceability ensures global buyers receive terminal blocks that conform to the same quality parameters regardless of shipment location.

Compliance with Global Electrical Standards

Export-ready 15EDGK connectors are engineered to meet or exceed international regulatory frameworks:

-

UL1059 (USA) – Terminal block safety and flammability compliance.

-

IEC60947-7-1 (EU) – Low-voltage terminal connection standards.

-

RoHS / REACH (Global) – Environmental and material safety.

-

CSA (Canada) – North American product certification for OEM use.

-

CE Declaration – Facilitates system integration across EU electrical designs.

By maintaining consistent compliance, 15EDGK exports can integrate seamlessly into industrial automation cabinets, inverters, and power management units worldwide.

Comparing 15EDGK with Other Pluggable Terminal Series

| Series | Pitch | Current Capacity | Connection Type | Best Use Case |

|---|---|---|---|---|

| 15EDGK | 5.08mm | Up to 15A | Screw clamp + plug lock | Automation & power control |

| DG301 | 3.81–5.08mm | 10–15A | Screw plug | Compact control panels |

| DG500 | 5.0mm | 20A | Pluggable + screw | High-power distribution |

| KF301 | 5.08mm | 10A | Simple screw type | Consumer electronics |

The 15EDGK series uniquely combines industrial durability with compact modularity, making it a preferred connector for export-driven OEM applications.

Application Mapping for Global Industries

15EDGK terminal blocks are used in environments where reliability, modularity, and serviceability converge:

-

Automation and PLC Systems: Quick-disconnect interface for field service and testing.

-

Renewable Energy Systems: Handles DC current in solar and inverter applications.

-

Power Distribution Cabinets: Ensures consistent torque and dielectric spacing.

-

HVAC and Building Controls: Supports dense wiring layouts with minimal heat buildup.

-

Telecommunication Equipment: Stable signal grounding in PCB-mounted systems.

Its design simplifies replacement and reduces downtime, providing measurable cost benefits to global integrators.

Configuration Selection by Use Environment

Selecting the right 15EDGK configuration requires matching electrical, mechanical, and environmental parameters.

| Application Condition | Engineering Priority | Recommended Configuration |

|---|---|---|

| High-Temperature Systems | Thermal stability | Nickel-plated terminals + PA66 housing |

| Frequent Plug/Unplug Operations | Contact endurance | Tin-plated terminals + reinforced headers |

| Vibration-Prone Machinery | Mechanical locking | Screw-lock + serrated washer |

| Outdoor or Humid Environments | Corrosion resistance | Anti-oxidation plating + sealing design |

| OEM/ODM Integration | Branding and customization | Custom logo engraving, modular color coding |

Procurement engineers should request UL file references, 3D CAD drawings, and material data sheets to verify specification alignment before ordering.

A supplier with in-house molding and plating control can ensure dimensional repeatability across high-volume exports.

Advancing Global Reliability Through Connector Innovation

The 15EDGK terminal block exemplifies how mechanical precision and regulatory compliance converge to deliver export-grade reliability.

Its modular structure and high contact integrity meet the rising demands of global power automation, where every millimeter of accuracy supports long-term system stability.

Zhongbo continues to lead in 15EDGK terminal block export production through automated assembly, strict UL/IEC validation, and flexible OEM cooperation—helping global manufacturers achieve safer, smarter, and more scalable electrical systems.

For export inquiries or technical collaboration, please visit our homepage or contact us.