Precision and Safety in Every Connection: Partnering with the Right Electrical Terminal Block Supplier

The Overlooked Foundation of Electrical Safety

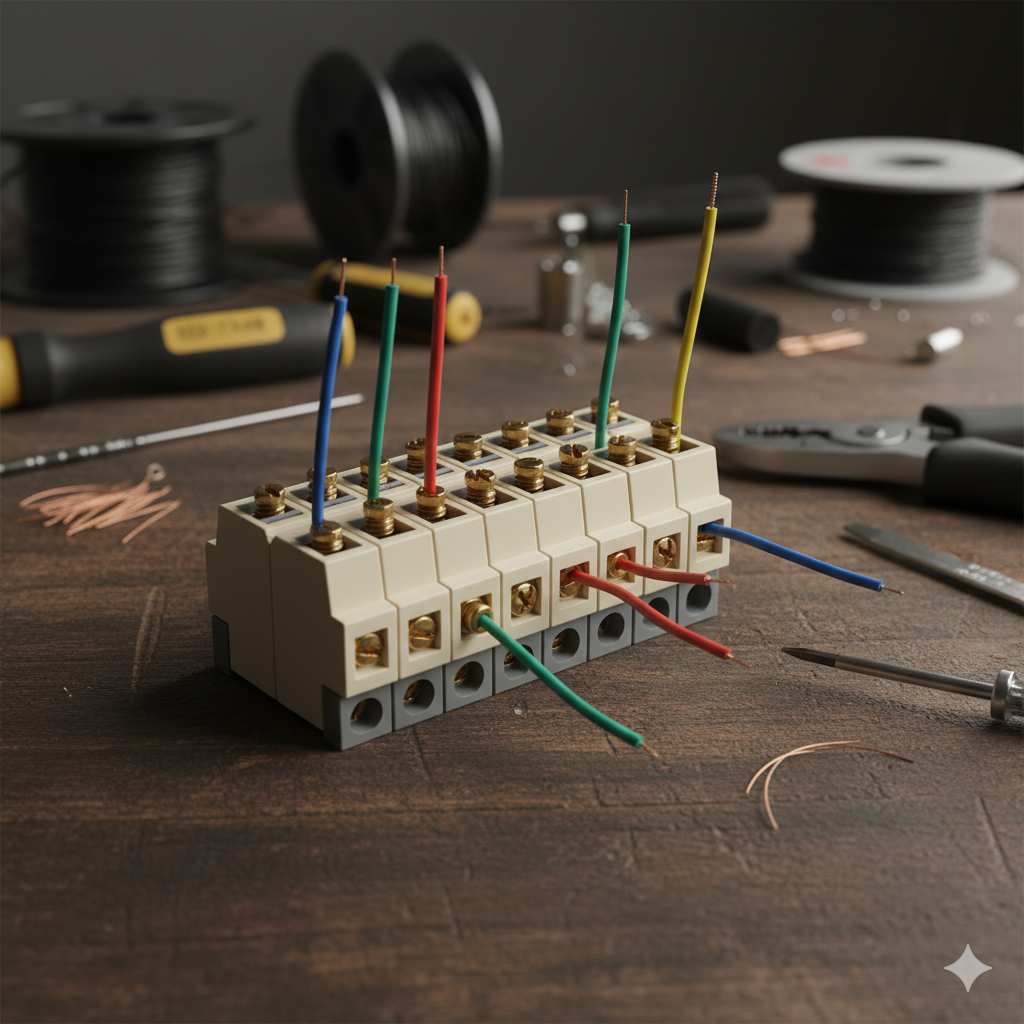

In industrial automation, the smallest component often carries the biggest responsibility.

Electrical terminal blocks are one of those silent heroes—reliable until they aren’t. A loose screw, a mismatched conductor size, or low-grade insulation can trigger failures that cascade across production lines.

Many manufacturers rely on generic suppliers who prioritize volume over verification. The result? Inconsistent torque values, uneven contact pressure, and uncertain compliance with UL or IEC standards.

In modern automation systems where safety, uptime, and scalability define success, the choice of an electrical terminal block supplier is not transactional—it’s strategic.

Principles of Reliable Electrical Connectivity

A dependable terminal block is the outcome of precise engineering, material discipline, and process control.

A true supplier doesn’t just ship products—they design systems for reliability.

-

Conductivity Optimization — Copper alloy contacts minimize resistance while maintaining torque stability.

-

Thermal Integrity — Housing materials such as PA66 and PBT resist deformation under continuous current load.

-

Insulation Design — Compliance with IEC 60947-7-1 ensures proper creepage and clearance distances.

-

Manufacturing Consistency — Automated assembly and vision inspection guarantee repeatable quality.

Behind every certified terminal block lies a manufacturing philosophy: reliability is engineered, not inspected in.

Standard Suppliers vs. Certified Partners

| Aspect | Generic Supplier | Certified Electrical Terminal Block Supplier |

|---|---|---|

| Certification | Often local or partial | UL, CE, CCC, RoHS compliant |

| Torque Tolerance | Manual | Automated, verified per batch |

| Housing Material | Mixed PA grades | Flame-retardant PA66/PBT (UL94 V-0) |

| Conductor Fit | Limited options | Custom sizing + spring or screw options |

| Batch Traceability | Minimal | Full QR-based tracking and test reports |

| Lifecycle Value | Low | Extended service life and safety margin |

Partnering with a certified supplier ensures that every terminal block not only meets design intent but also survives real-world stress conditions.

Supplier Integration with Engineering Intent

Modern electrical terminal block suppliers integrate upstream with OEM designers and downstream with automation distributors.

Their processes align with client specifications through:

-

Early Co-Design Collaboration — Providing CAD models and torque data during system layout.

-

Process-Linked Quality Control — Using torque-measurement sensors and dielectric testing per batch.

-

Regional Compliance Alignment — Mapping certifications (UL for North America, CE for EU, CCC for Asia).

-

Global Logistics Integration — Maintaining buffer stock near export ports for timely supply.

This integration transforms a simple procurement relationship into an engineering partnership, ensuring both safety and continuity.

Core Advantages of a Trusted Supplier

-

High Mechanical Precision — Ensures consistent clamping force for various conductor classes.

-

Heat and Flame Resistance — UL94 V-0 housings prevent deformation and ignition.

-

Regulatory Confidence — Products pre-certified for multiple export markets.

-

Faster Wiring and Maintenance — Push-in designs cut installation time by 30%.

-

Scalability Across Projects — Modular product series enable unified design across voltage ranges.

Every advantage adds up to what engineers value most—predictability.

Application Scenarios

-

Automation Control Panels — Multi-level terminals organize signal wiring and reduce space.

-

Renewable Energy Systems — 1000V DC-rated blocks maintain performance in outdoor conditions.

-

HVAC & Building Management — Pluggable terminals simplify wiring in distributed control networks.

-

Lighting & LED Drivers — Compact PCB terminal blocks ensure thermal stability.

-

Transportation Systems — Vibration-proof connections safeguard power continuity.

Selection Guide for Engineers

| Environment | Recommended Type | Key Feature |

|---|---|---|

| High Current | Screw Clamp | Larger copper area, lower resistance |

| Compact Panels | Push-In Type | Vertical entry, time-saving |

| High Vibration | Spring Type | Self-locking mechanism |

| High Humidity | PBT Housing | Moisture and chemical resistance |

| Multi-Voltage | Pluggable Block | Quick circuit modification |

Choose suppliers that provide mechanical drawings, torque data, and certification documents before final selection—proof of engineering, not marketing.

Frequently Asked Questions

Q1: What certifications should I verify before purchasing?

Ensure UL 1059 and IEC 60947-7-1 compliance, along with RoHS environmental conformity.

Q2: Can suppliers customize based on panel layout?

Yes. Many offer OEM support for pole count, color, or pitch variations.

Q3: How to test terminal block reliability?

Request temperature-rise, pull-out, and torque test data for each model.

Q4: What’s the usual delivery lead time?

3–5 weeks depending on certification extension and batch size.

Partnering for Long-Term System Integrity

A qualified electrical terminal block supplier is more than a vendor—it’s a contributor to your system’s long-term performance.

When you source from a certified, process-driven supplier, every terminal block becomes a guarantee of safety and repeatability.

To explore compliant, high-precision wiring components, visit our homepage or contact us via Contact Us.

Zhongbo delivers certified terminal block solutions engineered to power global industries with precision and trust.