Flexible Configurations for Every Industry: The OEM Advantage in Screw Terminal Block Supply

Adapting to Industry-Specific Electrical Demands

In today’s industrial landscape, electrical systems are anything but standardized. Each industry—from manufacturing and energy to transport and building automation—demands connection components that can handle distinct voltage levels, environmental conditions, and spatial constraints.

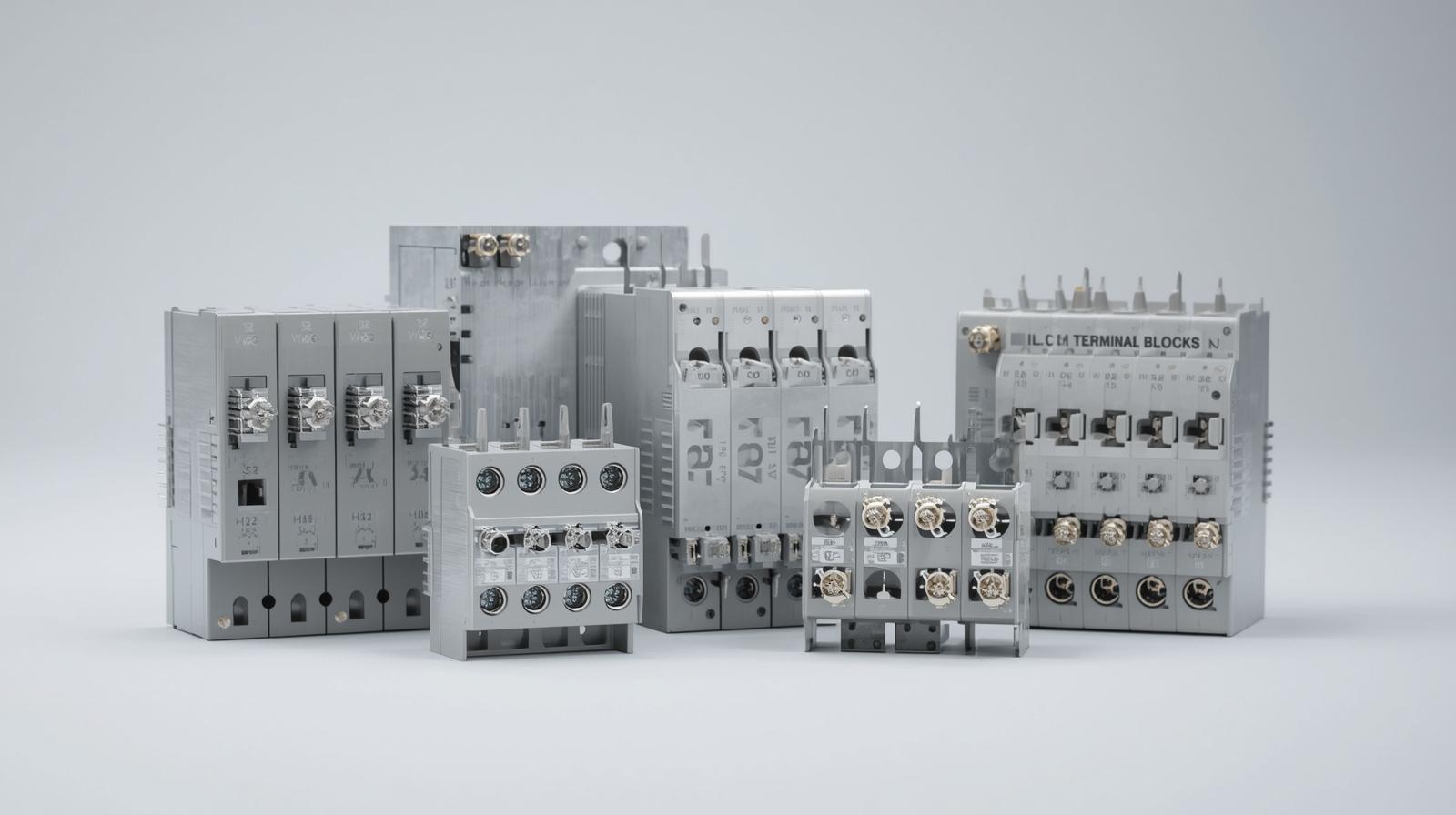

OEM screw terminal block suppliers bridge this gap by providing flexible designs that integrate seamlessly into existing systems while maintaining superior current capacity, vibration resistance, and installation simplicity.

These suppliers work closely with engineering teams to ensure compatibility across diverse setups—whether it’s compact control panels in HVAC systems or high-load switchgear in industrial automation. The adaptability of OEM configurations is what allows modern factories and smart grids to remain both safe and scalable.

Why OEM Flexibility Defines Competitive Advantage

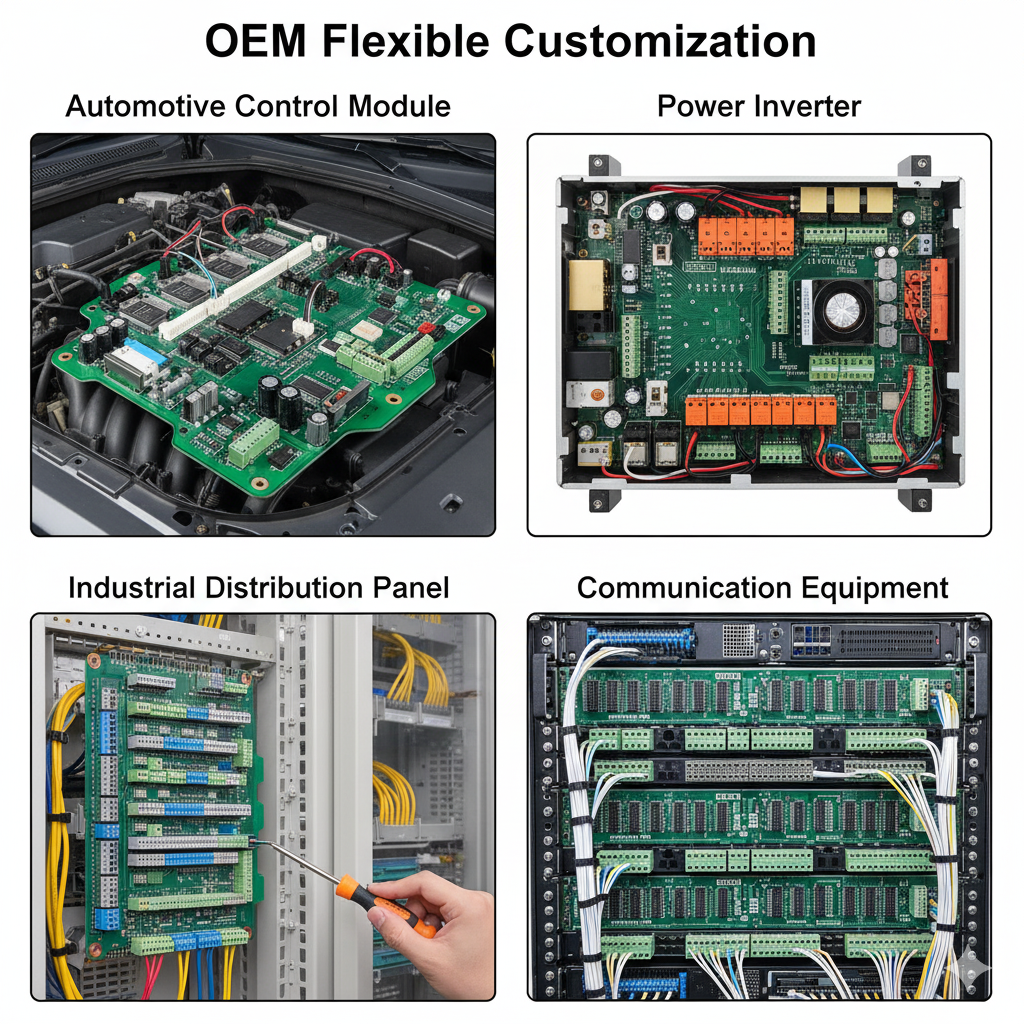

Customization in screw terminal block manufacturing isn’t just an aesthetic choice—it’s a competitive necessity. Industrial clients increasingly seek OEM partners that can adjust pitch sizes, terminal counts, and mounting methods without compromising safety or certification compliance (such as UL and IEC).

For instance, energy sector clients may prioritize heat dissipation and corrosion resistance, while transport infrastructure projects require shock-proof and vibration-stable assemblies.

By providing modular and tailored options, OEM suppliers enable:

-

Efficient integration with PLCs, relays, and circuit protection units

-

Streamlined assembly processes for production lines

-

Reduced maintenance time through tool-free wiring designs

This OEM-driven adaptability ensures that every terminal block configuration serves its functional environment optimally.

Industry Use Cases and Engineering Configurations

The following table illustrates how OEM flexibility benefits different industries through design and material optimization:

| Industry Application | OEM Configuration Advantage | Typical Design Adaptation |

|---|---|---|

| Industrial Automation | Compact pitch terminals for space-saving control cabinets | Modular blocks with quick-release features |

| Energy Systems | Heat-resistant and high-current models | Copper alloy contacts and reinforced insulation |

| Transportation | Shock-proof configurations for mobile equipment | Vibration-resistant spring clamps |

| Building Automation | Streamlined installation and labeling | Plug-in designs with pre-numbered identifiers |

Each configuration is engineered for operational continuity—reducing downtime and ensuring compliance with international safety standards.

Practical Design Insights from OEM Collaboration

Close collaboration between clients and OEM suppliers leads to tangible design efficiencies.

Engineers can specify terminal spacing, mounting orientation, or wire entry angles according to project needs. Through iterative design and prototyping, OEMs deliver fit-for-purpose solutions that outperform generic catalog products.

Advanced 3D modeling and automated testing also accelerate development, ensuring every component achieves peak conductivity and minimal resistance loss under real-world conditions.

Partnering with Trusted OEM Suppliers for Long-Term Value

OEM suppliers who combine engineering precision, material expertise, and scalability are essential partners for industrial manufacturers seeking long-term value.

ZhongBo stands out for its integration of R&D, testing, and automated production, providing clients across automation, power, and machinery sectors with certified, flexible terminal block solutions that ensure safety, efficiency, and global compliance.

To explore customized OEM configurations for your next project, visit ZhongBo’s homepage or contact our team for detailed specifications and collaboration options.