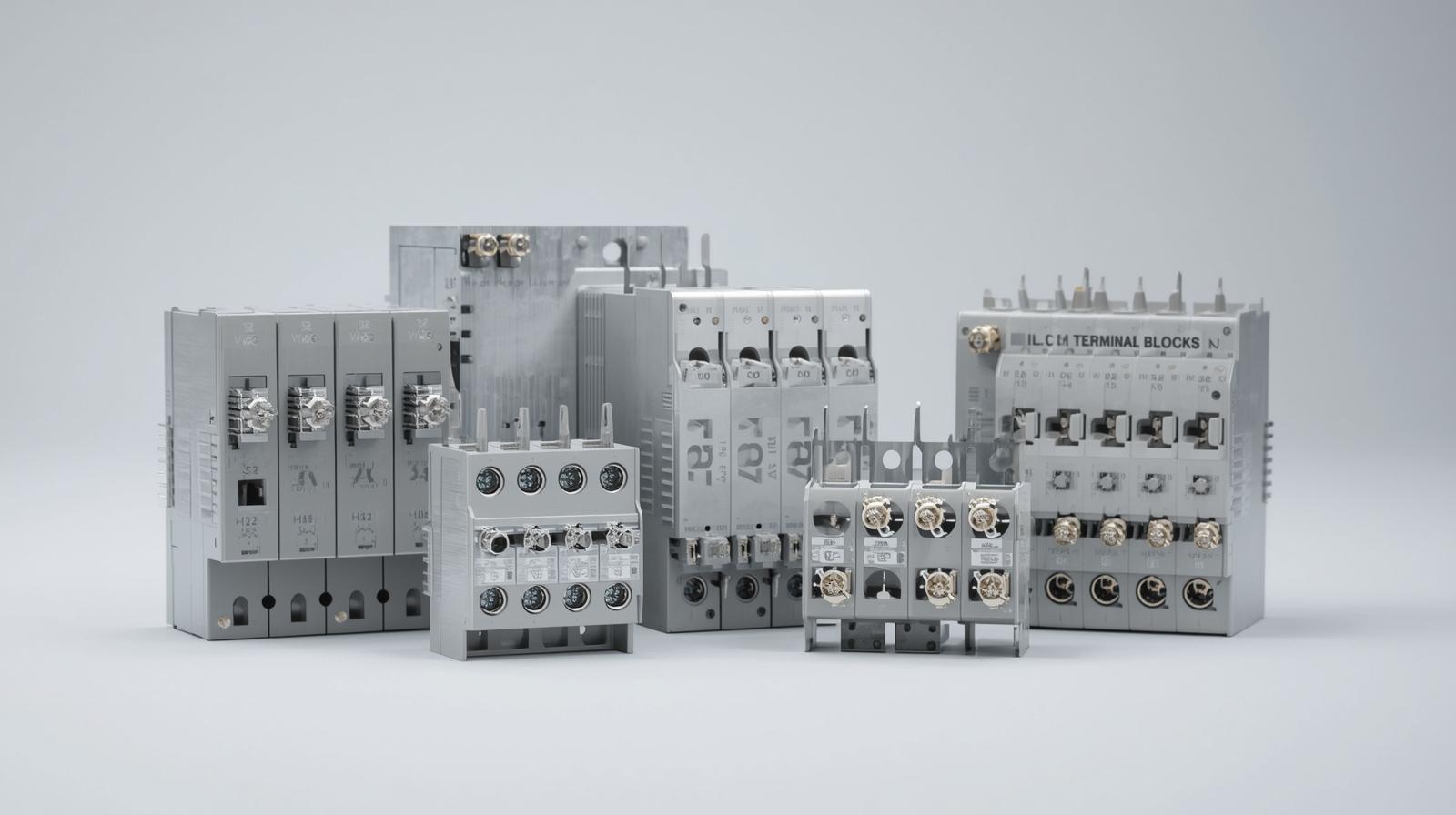

Spring Clamp Terminal Block Factory Innovates Electrical Systems

Rethinking Electrical Connections in Modern Industries

Electrical systems across manufacturing, energy, and automation are under constant pressure to improve efficiency, safety, and maintainability. Traditional screw terminal blocks, while proven, present ongoing challenges such as loosening under vibration, lengthy installation time, and the need for routine torque inspection.

Factories and system integrators increasingly seek alternatives that simplify wiring without compromising current-carrying performance. This shift has placed spring clamp terminal block factories at the forefront of innovation—delivering connection solutions designed for reliability under demanding operating conditions.

Engineering Principle: The Constant Pressure Advantage

At the core of spring clamp technology lies a simple mechanical principle: constant contact pressure through a spring mechanism.

Unlike screw terminals, where clamping force depends on manual tightening, spring clamps maintain stable pressure on the conductor automatically. This design eliminates torque dependency, ensuring consistent electrical contact even when exposed to temperature variations, vibration, or mechanical stress.

Spring terminals typically employ high-strength stainless steel springs combined with copper alloy current bars, enabling both excellent conductivity and mechanical endurance. The result is a connection that resists loosening, oxidation, and fatigue—key issues in environments requiring uninterrupted operation such as production lines, control cabinets, and transport systems.

Comparison: Spring vs. Screw Termination in Real Applications

| Feature | Spring Clamp Terminal Blocks | Screw Terminal Blocks |

|---|---|---|

| Connection Pressure | Constant, self-adjusting | Depends on tightening torque |

| Maintenance Needs | Minimal, no re-torque required | Periodic re-tightening needed |

| Vibration Resistance | Excellent, unaffected by motion | May loosen under vibration |

| Installation Time | Rapid, tool-free or push-in design | Slower, requires screwdriver |

| Temperature Stability | High, due to elastic contact system | May vary with expansion/contraction |

The comparison reveals why modern electrical systems—especially those using modular automation—are increasingly replacing screw-type connections with spring clamp alternatives.

While screw terminals remain useful for heavy-duty power circuits, spring clamps dominate in control, signal, and instrumentation applications where speed, stability, and space efficiency matter most.

Industrial Applications Driving Adoption

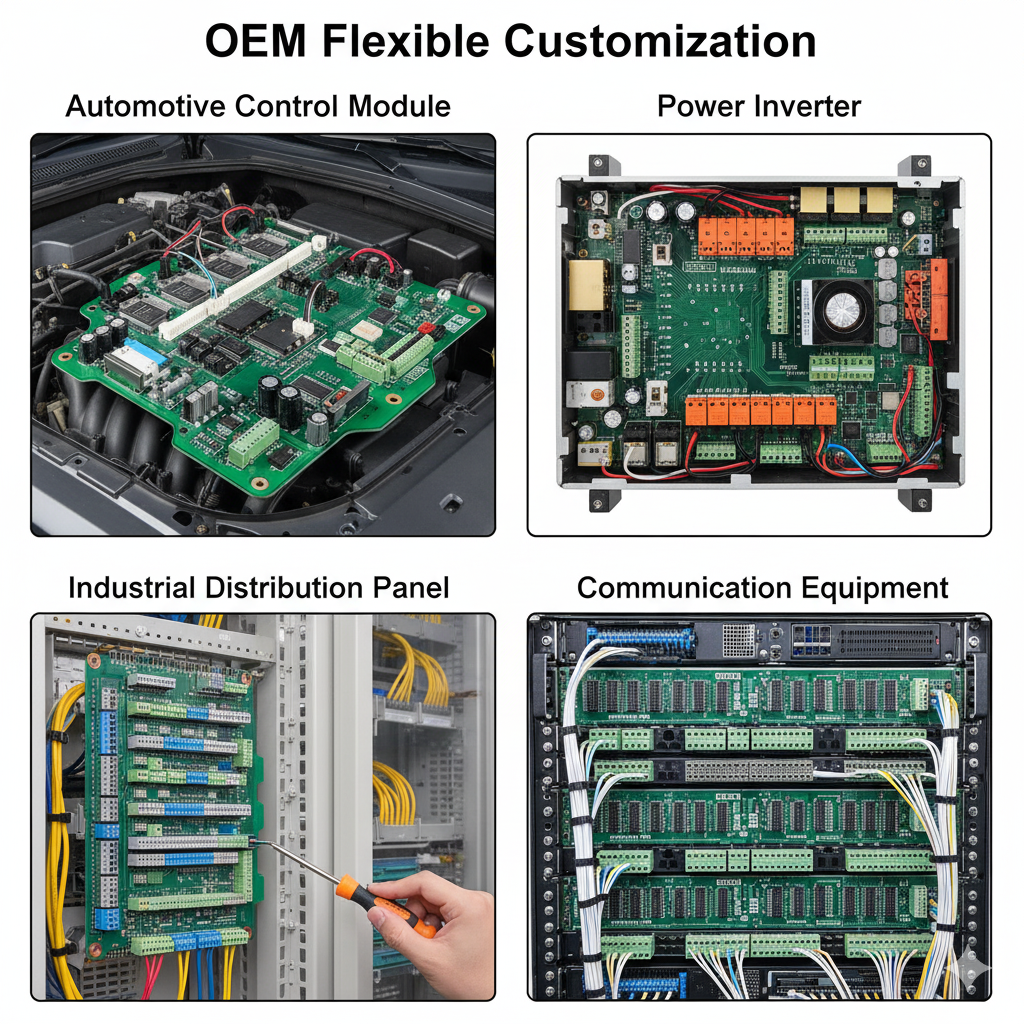

Spring clamp terminal block factories now serve a broad spectrum of industries, each emphasizing different engineering priorities:

-

Automation Systems – Compact wiring for PLCs, I/O modules, and relay interfaces; tool-free maintenance supports quick system reconfiguration.

-

Renewable Energy Installations – High reliability under vibration and temperature variation in solar and wind applications.

-

Building Management Systems – Streamlined wiring of sensors, controllers, and lighting modules within confined spaces.

-

Transportation and Rail – Long-term vibration resistance and fire-safe insulation ensure compliance with EN and UL standards.

By optimizing spring tension, housing geometry, and insulation materials, factories adapt the terminal block’s internal design to each environment. This customization ensures both safety and mechanical endurance across different current levels and wiring densities.

Practical Guidance: Selecting and Implementing Spring Clamp Terminals

When integrating spring clamp terminals into electrical panels, engineers should consider three key parameters:

-

Conductor Type and Size – Match the clamping force to the wire gauge and insulation type to prevent micro-gaps.

-

Current Load Capacity – Select models with ample cross-sectional area and thermal headroom.

-

Installation Density – For space-critical applications, multi-level spring terminals or push-in designs provide compact alternatives.

Properly implemented, spring clamp terminals reduce downtime and simplify preventive maintenance—especially in distributed control systems (DCS) and energy management modules.

Future Outlook and Factory Innovation

Leading spring clamp terminal block factories integrate automation in both design and testing processes. Precision metal forming, robotic assembly, and automated contact resistance testing ensure repeatable quality.

Factories increasingly apply data-driven design optimization—analyzing contact pressure distribution, thermal dissipation, and vibration endurance using simulation tools—to achieve predictive reliability before mass production.

This engineering-driven approach ensures consistent performance, meeting international standards such as IEC 60947 and UL 1059 while supporting global OEM clients with scalable production.

Conclusion: Building Reliability Through Design Evolution

The transition from screw-based to spring clamp connections marks a broader transformation in electrical design philosophy—from manual assembly toward automated, maintenance-free wiring.

Spring clamp terminal block factories now play a pivotal role in this shift, supplying components that align with modern engineering values: efficiency, safety, and long-term reliability.

For system designers seeking dependable connection solutions that minimize maintenance and enhance scalability, spring clamp terminals represent a mature, forward-looking choice in electrical system design.

To explore more about industrial connection solutions and OEM collaboration options, visit ZhongBo’s homepage or contact our engineering team.