Mastering Industrial Efficiency with Feed-Through Terminal Block OEM

Why Efficiency Starts with Connection Design

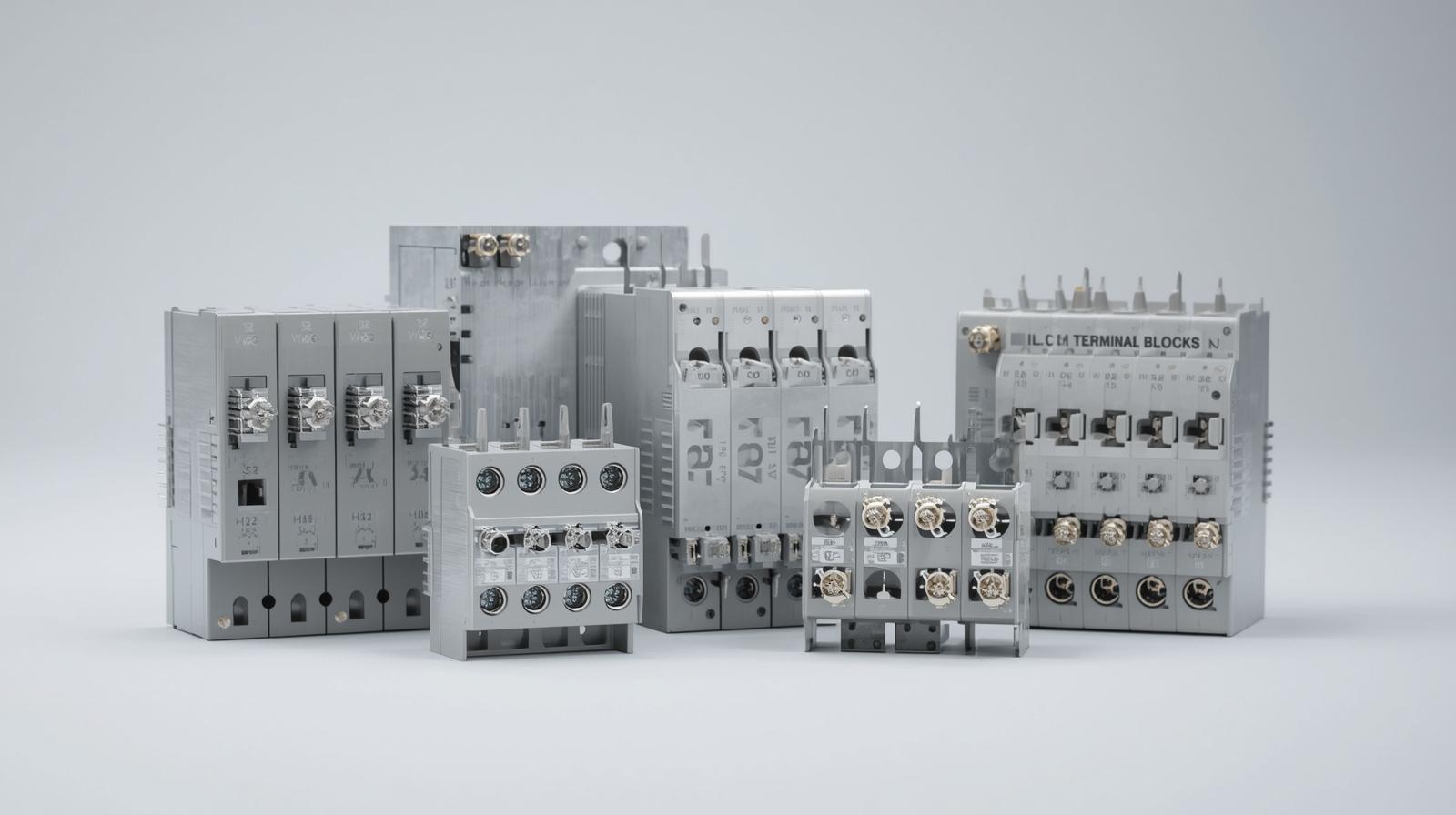

In every modern factory, efficiency depends on more than machines — it depends on how electricity is distributed. Feed-through terminal blocks form the backbone of industrial wiring systems, providing safe, consistent, and compact current transfer between circuits. However, many operations still face common problems: excessive wiring complexity, overheating under heavy loads, and delays in maintenance caused by unclear terminal labeling or limited access.

OEM feed-through terminal block manufacturing addresses these pain points directly. By customizing the spacing, current capacity, and insulation design, OEMs ensure that terminal blocks match specific voltage levels, installation layouts, and safety requirements in each industry.

How Feed-Through Terminal Blocks Optimize Electrical Systems

Unlike traditional connectors, feed-through terminal blocks maintain continuous power flow without interruption between input and output sides. This structure reduces contact points, which in turn minimizes resistance and heat buildup.

Key engineering advantages include:

-

Compact Layout: Saves up to 30% cabinet space compared to screw-based assemblies.

-

High Current Handling: Suitable for systems exceeding 40A continuous operation.

-

Safe Wiring Access: Double-entry design allows faster installation and inspection.

-

Thermal Reliability: Reinforced housing and metal alloys prevent heat deformation.

Each of these benefits helps factories achieve greater electrical efficiency, aligning with global standards such as IEC 60947-7-1 and UL 1059, ensuring durability even under continuous industrial operation.

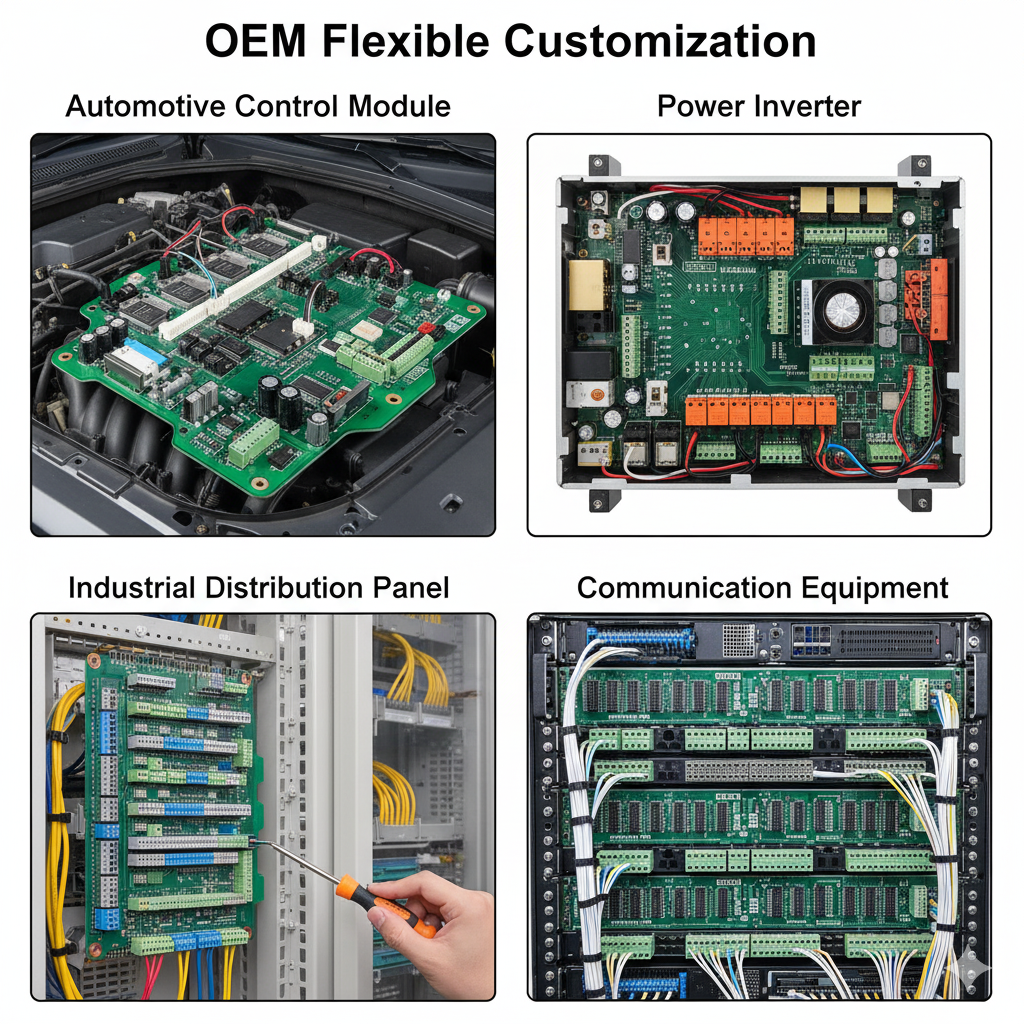

OEM Flexibility That Drives Real-World Impact

Feed-through terminal block OEM services make it possible to adapt products to unique engineering and environmental conditions.

Depending on the project, customization may focus on:

-

Voltage Range: Adjusting creepage distances for low- and high-voltage systems.

-

Material Type: Using flame-retardant polyamide or high-temperature-resistant composites.

-

Mounting Methods: Supporting DIN rail or PCB integration for automation panels.

-

Color Coding: Simplifying maintenance and minimizing wiring errors.

-

Screw or Spring Mechanisms: Providing flexibility for different assembly preferences.

Through OEM design collaboration, manufacturers can eliminate inefficiencies before they appear — saving time, reducing rework, and increasing safety margins in every control cabinet.

Comparison: Standard vs. OEM Feed-Through Terminal Blocks

| Feature | Standard Terminal Block | OEM Feed-Through Terminal Block |

|---|---|---|

| Design | Fixed dimensions | Tailored dimensions and spacing |

| Certification | General CE compliance | IEC, UL, and project-specific testing |

| Wiring Speed | Manual installation | Optimized for automated assembly |

| Heat Resistance | Up to 80°C | Extended to 120°C with reinforced alloys |

| Application | General wiring | Industrial automation, power stations, HVAC systems |

This comparison highlights how OEM customization can transform terminal blocks into high-performance components that actively improve system reliability.

Applications That Demand OEM Feed-Through Design

The advantages of OEM feed-through terminal blocks become most visible in sectors that demand precision and uptime.

-

Industrial Automation: Enables compact wiring in modular control panels.

-

Energy Infrastructure: Ensures reliable power transfer in solar and grid systems.

-

Transportation and Rail: Provides vibration-proof performance and heat tolerance.

-

Building Management Systems: Simplifies maintenance and circuit identification.

-

Heavy Equipment Manufacturing: Delivers stable electrical paths under high mechanical stress.

In each of these fields, design consistency, maintenance ease, and long-term durability directly influence productivity and cost savings.

Common Buyer Questions and Practical Answers

Q1: What distinguishes an OEM feed-through terminal block from standard models?

OEM designs are created according to the user’s environment, including voltage, temperature, and assembly needs — offering both better safety margins and longer lifecycle.

Q2: How are global certifications handled?

Manufacturers like ZhongBo ensure that every customized batch passes ISO9001:2015 quality control and international certifications including IEC 60947, CE, and UL standards.

Q3: Can OEM feed-through terminal blocks improve energy efficiency?

Yes. Optimized contact geometry and conductive materials reduce resistance and power loss, helping meet modern energy efficiency requirements.

ZhongBo’s Strength: Reliability, Precision, and Global Reach

At ZhongBo, every feed-through terminal block is designed with industrial precision and tested under simulated working conditions — including thermal cycling, dielectric strength, and torque performance.

The company’s automated production lines, CNC metal processing, and in-house testing lab guarantee that every product maintains stable performance even under harsh operating environments.

ZhongBo also offers OEM engineering consultation, enabling global clients to design terminal blocks that meet both regional standards and custom performance needs.

With these strengths, ZhongBo stands as more than a supplier — it’s a partner in optimizing power systems and automation reliability worldwide.

To learn more about our OEM terminal block solutions, visit our homepage or get in touch via our contact page.