Global Terminal Block Sourcing for Reliable Industrial Connectivity

In a world of distributed manufacturing and multi-regional assembly lines, global terminal block sourcing is now a core strategy for maintaining both cost efficiency and product reliability.

From automotive control panels in Mexico to solar combiner boxes in India, OEMs and system designers depend on international suppliers to provide standardized, certified, and scalable terminal block solutions. The shift toward automation and electrification makes sourcing not just a logistical task — but a design decision that directly affects safety, uptime, and compliance.

The Changing Landscape of Electrical Component Supply

Industrial supply chains are no longer regional. Electrical OEMs increasingly design products in one country, assemble them in another, and distribute them globally. This means terminal blocks must meet multiple regional certifications and operate seamlessly under diverse electrical environments.

Key sourcing challenges include:

-

Meeting different voltage standards (UL for North America, CE for Europe, CCC for China)

-

Managing temperature and humidity variations across climates

-

Balancing cost efficiency with durability and safety

-

Ensuring consistent supply and interchangeable parts across multiple sites

As a result, multinational buyers now prioritize suppliers capable of multi-standard compliance, global logistics coverage, and technical documentation in multiple languages.

Standards and Compliance: The Backbone of Global Trade

Sourcing terminal blocks across borders requires deep knowledge of international electrical standards.

| Region | Common Standards | Voltage Range | Testing Authority |

|---|---|---|---|

| North America | UL1059, CSA C22.2 | 300–600V | UL / CSA |

| Europe | IEC60947-7-1 / EN60947 | 400–1000V | TUV / CE |

| Asia-Pacific | GB / CCC | 250–1000V | CQC / CCC |

| Global Export Models | Dual-certified (UL+CE) | Up to 1000V DC | Intertek / SGS |

This dual-certification strategy allows manufacturers to reduce SKUs and streamline compliance for multi-country installations — a vital advantage for OEMs exporting machinery or electrical panels worldwide.

Balancing Quality, Lead Time, and Cost in Sourcing Decisions

Choosing the right sourcing strategy is about optimization, not compromise.

| Sourcing Model | Benefit | Typical Use Case |

|---|---|---|

| Single Global Supplier | Simplified logistics and uniform standards | Multinational OEMs |

| Regional Partner Network | Faster delivery and local support | Distributors & integrators |

| OEM Private Label Cooperation | Branding control + customized design | Export manufacturers |

| Hybrid (Global + Local) | Balances cost, lead time, and service | Automation projects with phased deployment |

A strong sourcing plan includes technical transparency, such as 3D CAD models, datasheets, and test certificates that enable engineers to verify compatibility early in design.

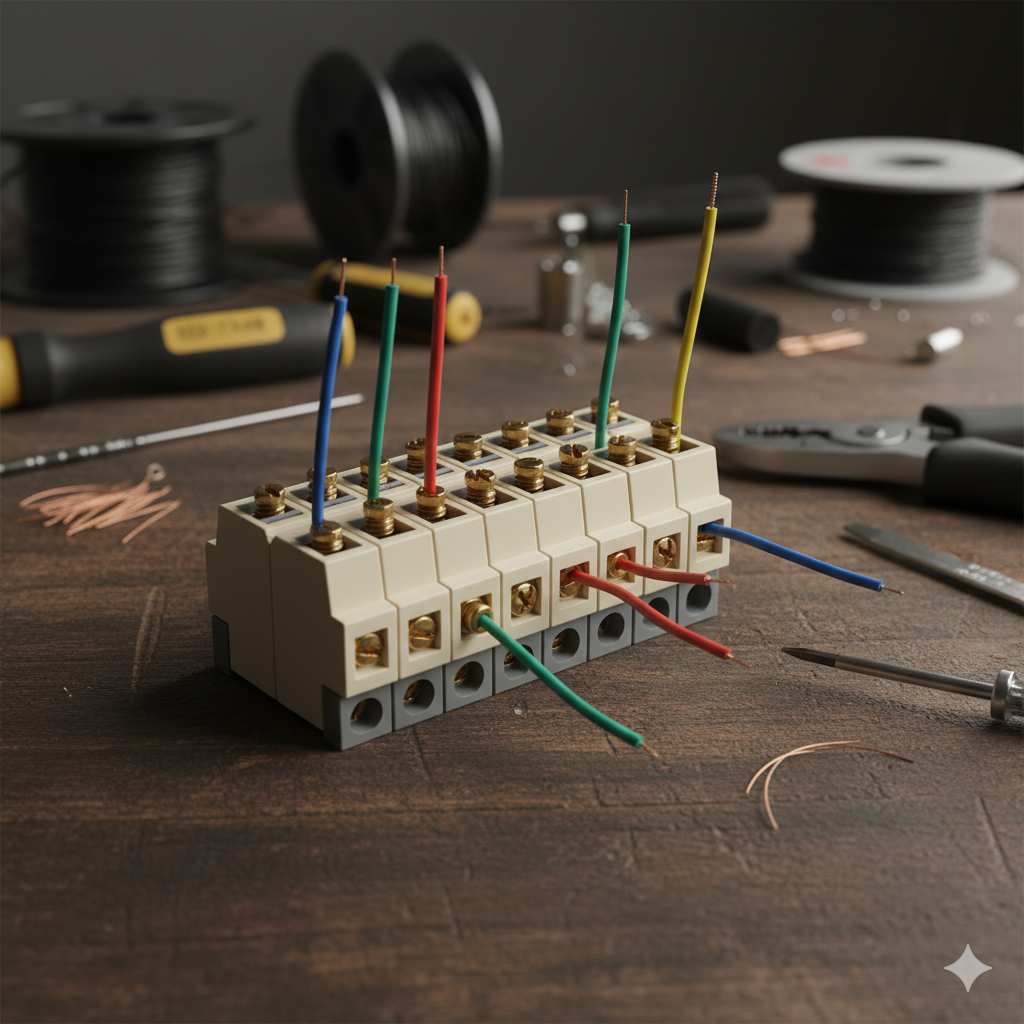

Applications That Depend on Reliable Global Sourcing

Reliable terminal block sourcing supports critical functions across multiple sectors:

-

Industrial automation and control panels — ensuring consistent wiring across global factories

-

Renewable energy installations — with high-current, weather-resistant terminal blocks for solar and wind

-

HVAC and building management systems — modular designs for fast field service and panel upgrades

-

Automotive and EV systems — vibration-proof connections supporting distributed assembly lines

-

Power distribution and switchgear — high-temperature endurance for continuous heavy current flow

Global OEMs now view sourcing not as an afterthought but as a strategic component of quality assurance and regulatory compliance.

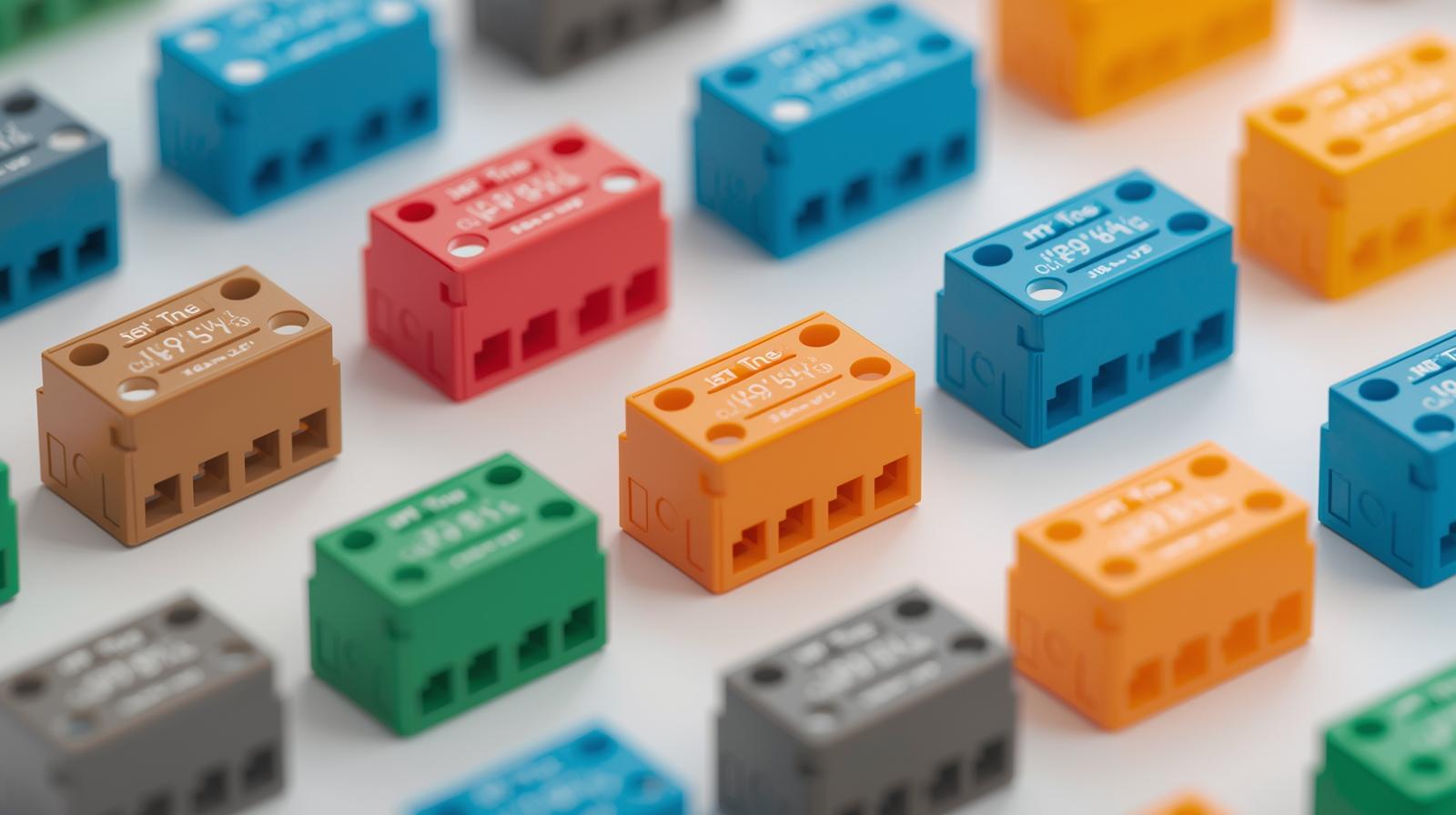

Practical Recommendations for Effective Global Sourcing

For engineers and procurement teams, the following best practices help streamline international sourcing:

-

Verify compliance documentation early — Request UL, CE, or TUV certificates before contract finalization.

-

Evaluate environmental adaptability — For high-humidity or high-vibration zones, choose PA66 or PBT housings with V-0 flame resistance.

-

Plan safety margins — Always select terminal blocks rated 20–30% above operational voltage.

-

Use modular and pluggable designs — Simplifies replacement in overseas projects without retraining staff.

-

Balance cost and continuity — Long-term consistency often outweighs marginal price savings.

When selecting a partner, prioritize suppliers offering transparent traceability, predictable logistics, and cross-standard design support.

Frequently Asked Questions

Q1: How can a company ensure consistent product specifications across different regions?

A: Choose suppliers offering dual-certified models (UL + CE) and provide unified datasheets with global compliance documentation.

Q2: Are Chinese suppliers reliable for large-scale terminal block exports?

A: Yes. Established manufacturers from Ningbo and Wenzhou regions provide ISO-certified, export-ready products widely used in EU and U.S. markets.

Q3: What’s the biggest sourcing risk in terminal block imports?

A: Lack of standard alignment between project design and supplier specification — always verify compliance before mass procurement.

Q4: Can suppliers provide OEM or private-label terminal blocks?

A: Many global manufacturers offer tooling customization and logo branding for distributors and system builders.

Global Supply Chain Reliability Begins with Trusted Partnerships

Global terminal block sourcing isn’t just about finding the lowest quote — it’s about building supply reliability that protects end users, reduces downtime, and ensures compliance worldwide.

Suppliers with strong manufacturing depth, certification portfolios, and export logistics capabilities create a long-term competitive edge for OEM buyers.

Zhongbo supports global customers with fully certified terminal blocks, modular designs, and OEM-ready supply solutions built for automation, energy, and power distribution systems.

To discuss sourcing options or custom configurations, visit our homepage or contact us.