Supplying Connectivity: How Global Terminal Block Manufacturers Support India’s Growing Import Market

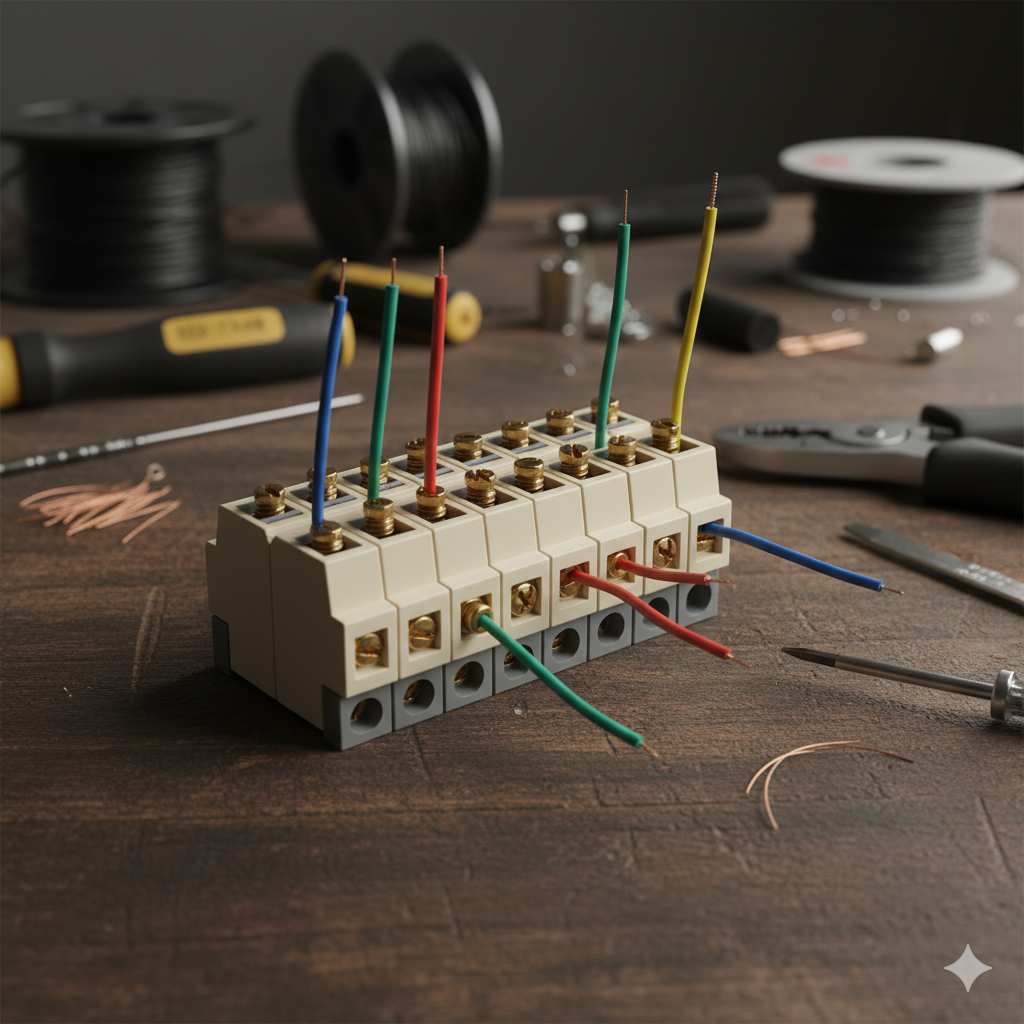

As India accelerates its industrial automation and renewable energy transition, the demand for high-quality imported terminal blocks is rising rapidly.

From automotive plants in Pune to solar installations in Gujarat, local integrators rely on certified international suppliers to deliver components that meet global safety and performance benchmarks.

For both importers and OEM buyers, selecting the right India import terminal block supplier means ensuring each connection stands up to the region’s demanding environmental and operational conditions.

India’s Expanding Demand for Industrial Wiring Components

India’s economic growth has led to surging investment in manufacturing automation, infrastructure modernization, and clean energy systems.

These industries require robust electrical connectivity — particularly terminal blocks — for safe and modular control wiring.

Key market drivers include:

-

Automation adoption in automotive, packaging, and process industries

-

Energy infrastructure upgrades with solar, wind, and EV charging networks

-

Smart building and HVAC projects requiring compact, modular wiring systems

-

Government initiatives like Make in India boosting local assembly while importing critical components

As a result, Indian distributors and OEMs increasingly source terminal blocks from China, Europe, and other Asian manufacturing hubs, prioritizing consistent quality and global compliance.

Engineering Standards in Imported Terminal Blocks

For successful import and integration, terminal blocks must comply with both international standards and Indian safety requirements.

| Technical Aspect | Specification | Standard / Directive |

|---|---|---|

| Voltage Rating | 300V–1000V | IEC60947 / UL1059 |

| Housing Material | UL94 V-0 PA66 / PBT | Fire-retardant and halogen-free |

| Temperature Range | -40°C to +125°C | Suitable for tropical climates |

| Conductor Type | Tin-plated brass / copper alloy | High conductivity, anti-corrosion |

| Testing Protocol | Torque and dielectric tests | Verified by CE / UL / TUV labs |

This combination ensures that imported terminal blocks can be safely used in India’s humid, high-temperature, and vibration-prone environments — whether for factory automation or outdoor solar power systems.

Global Supply Chains Serving Indian Buyers

| Supply Source | Strength | Typical Application |

|---|---|---|

| China (Ningbo, Wenzhou) | Large-scale, cost-efficient OEM production | Industrial automation and energy systems |

| Europe (Germany, Italy) | Precision engineering, UL & CE dual certification | High-end control and instrumentation |

| Taiwan / Korea | Mid-volume customization with fast lead times | HVAC, electronics, and automation |

| Local Indian Importers | Regional warehousing and technical support | Distribution and maintenance services |

Global suppliers bridge design and compliance gaps, allowing Indian importers to access ready-to-integrate CE/UL-certified components that align with local standards.

Selecting the Right Terminal Block for Indian Applications

Because India’s industries operate across diverse climates and system types, choosing the correct terminal block is crucial.

-

For industrial automation and robotics

Use spring-clamp or screw terminals to ensure vibration resistance and secure wire retention. -

For HVAC and smart building systems

Choose modular pluggable terminals for easy maintenance and quick panel rewiring. -

For renewable energy and solar applications

Opt for high-voltage DC terminal blocks (up to 1000V) made with anti-tracking insulation for outdoor reliability. -

For automotive and EV manufacturing

Select compact, heat-resistant connectors tested under UL1059 or IEC60947 for stable current flow in high-vibration settings.

By aligning product type with environment and operational stress, Indian importers can extend system lifespan and improve electrical reliability.

Frequently Asked Questions

Q1: Do imported terminal blocks need BIS certification in India?

A: For control and low-voltage devices, international standards (UL/CE/IEC) are typically accepted, but local testing may be required for public projects.

Q2: Which suppliers are best for OEM collaboration?

A: Leading Chinese and European manufacturers with in-house tooling and UL/CE certification are preferred for OEM and private-label orders.

Q3: What are the average lead times for import shipments?

A: 20–30 days by sea freight from China or 7–10 days via air cargo for urgent projects.

Q4: Are imported terminal blocks compatible with Indian wiring sizes?

A: Yes. Global suppliers manufacture terminal blocks supporting 0.5–35mm² wire sizes to match IS standards.

Building Safer Systems Through Global Supply Partnerships

India’s industrial modernization depends on reliable electrical infrastructure — and imported terminal blocks are a critical link in that chain.

By sourcing from certified global suppliers, Indian buyers can ensure system safety, regulatory compliance, and long-term reliability.

Zhongbo continues to support India’s fast-growing automation, HVAC, and renewable sectors with certified, export-ready terminal block solutions tailored for local installation environments.

For import coordination or OEM cooperation, visit our homepage or contact us.