将终端块无缝整合到您的PCB设计中对于制造性,可靠性和可用性至关重要。遵循以下关键技巧:

-

精确的足迹精度:

-

使用精确的制造商的土地图案数据表尺寸(垫尺寸,间距)。

-

双检查孔的双孔和SMT垫的对齐方式的双检查孔尺寸。即使是轻微的错误也会导致未对准或焊接问题。

-

-

考虑组装与返工:

-

清除:确保块周围有足够的空间,以焊接铁杆,螺丝刀或插入工具。不要将高的组件放在太近的地方。

-

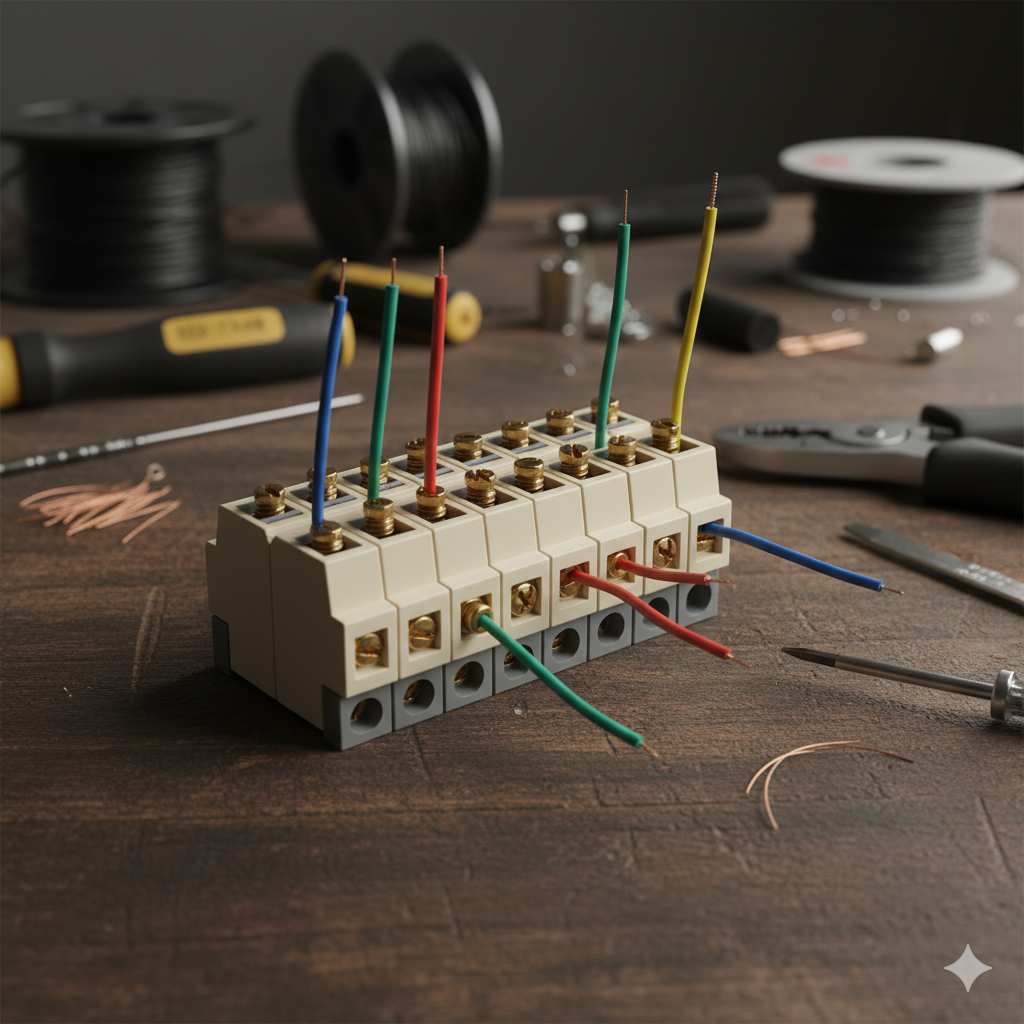

方向:板边缘附近的位置块,可轻松访问电线。东方螺钉头或推入开口。

-

极化:包括清晰的极化标记(丝线),以防止插入不正确。

-

-

当前的处理和跟踪尺寸:

-

连接到终端块的轨迹必须处理相同的电流。根据电流和铜重使用PCB痕量宽度计算器。

-

避免在终端垫附近缩小痕迹。使用泪珠,痕迹与垫子相遇以达到强度。

-

-

应变缓解和机械支持:

-

对于处理受运动或应变的电线的块,请结合机械锚:安装孔,板锁或支架。

-

确保PCB本身在端子块连接点附近得到充分支持。

-

-

标签和文档:

-

在旁边使用清晰,耐用的丝网印刷标签每个终端(例如,“ L”,“ N”,“ GND”,“ in+”,“ OUT-”)。

-

将标记与原理图和接线图精确匹配。一致的颜色编码(如果在块上使用)也应反映。

-

奖励提示:尽早与您的PCB制造商和EMS提供商讨论终端块放置,以识别潜在的DFM(用于制造性设计)或DFA(用于组装设计)问题。精心计划的布局节省了时间,成本和头痛。中bo提供了全面的CAD模型和详细的图纸。