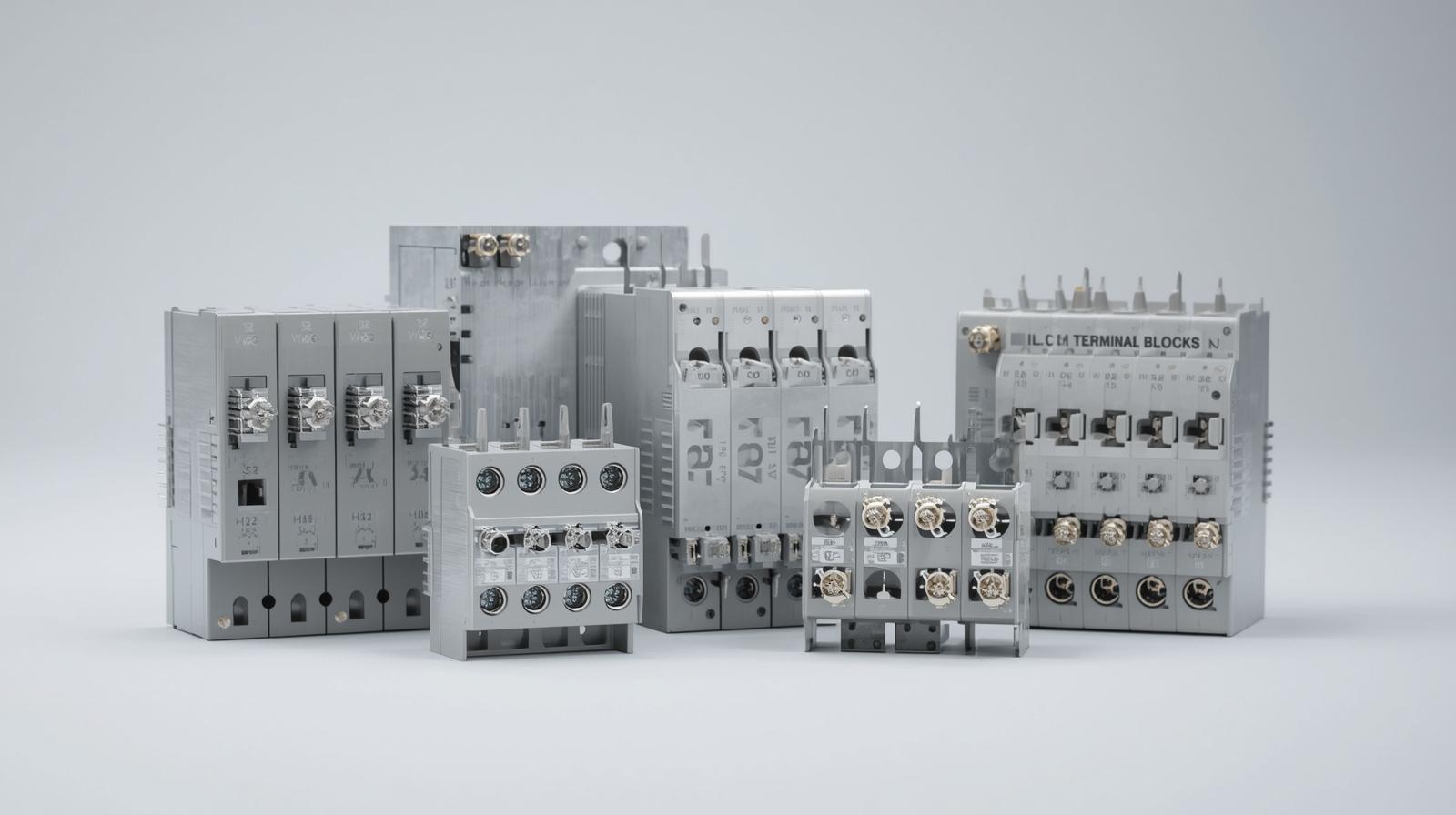

Terminal Block Manufacturer: Innovating Electrical Connectivity

Evolving Industry Challenges in Electrical Connectivity

In industrial automation, renewable energy, and building systems, electrical reliability defines operational safety and uptime. Yet engineers face increasing challenges—rising power density, limited panel space, and stricter global standards (IEC, UL, RoHS). Traditional terminal blocks often fail to meet modern expectations for modularity, compactness, and maintenance efficiency.

Manufacturers like ZhongBo have recognized these pressures and are reshaping the terminal block landscape by integrating engineering precision with application-driven design.

Core Principles Behind Modern Terminal Block Design

The new generation of terminal blocks is built around three principles — mechanical integrity, electrical performance, and environmental durability.

| Principle | Description | Engineering Approach |

|---|---|---|

| Mechanical Integrity | Ensures vibration and torque resistance under continuous operation. | Precision-molded housings, anti-loosening screw systems, and reinforced metal contacts. |

| Electrical Performance | Reduces contact resistance and energy loss. | Copper alloy conductors and multi-layer plating to ensure consistent conductivity. |

| Environmental Durability | Supports harsh conditions in automation and energy systems. | Flame-retardant and temperature-resistant polymer materials compliant with IEC/UL standards. |

This combination allows terminal blocks to perform reliably in control panels, power converters, and photovoltaic systems where long-term performance is critical.

Comparing Modern Terminal Block Technologies

To meet diverse application demands, manufacturers now produce multiple types—each offering distinct advantages:

| Type | Ideal Use | Key Advantage |

|---|---|---|

| Screw Terminal Block | Heavy-duty industrial systems | Strong mechanical hold for large conductors |

| Spring Clamp Terminal Block | Automation and sensor circuits | Fast wiring and vibration resistance |

| Feed-through Terminal Block | Energy and control distribution | Compact form and secure connections |

| Plug-in Terminal Block | Modular or replaceable systems | Easy maintenance and flexible configuration |

Rather than competing, these types complement each other in complex systems—helping OEMs design hybrid wiring architectures that balance speed, safety, and scalability.

Practical Applications Across Industries

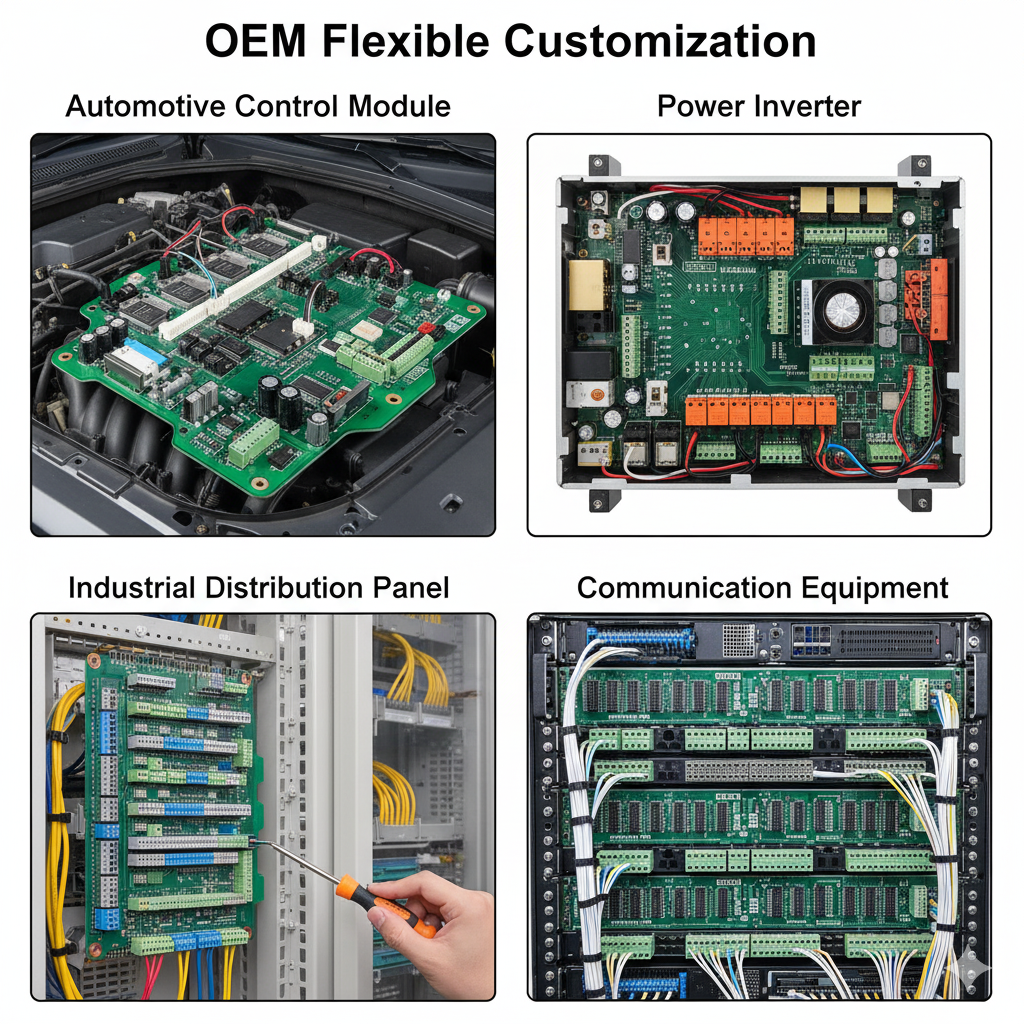

Modern terminal block manufacturers such as ZhongBo now design solutions tailored for industry-specific needs:

-

Energy Systems: For solar inverters, battery storage, and power distribution panels, terminal blocks provide high-current and surge-resistant connections.

-

Automation and Machinery: Modular blocks simplify installation in PLC and control cabinets, reducing wiring errors and downtime.

-

Transportation: Vibration-proof connectors ensure secure wiring in rail and EV systems.

-

Construction and HVAC: Compact and flame-retardant designs support distributed building automation and environmental controls.

These use cases highlight how terminal blocks have evolved from simple connectors into strategic components of power reliability and efficiency.

Guidance for Engineers and OEM Buyers

When selecting or sourcing from a terminal block manufacturer, key evaluation criteria include:

-

Compliance: Ensure IEC 60947-7 and UL standards certification for international trade.

-

Customization: Choose OEM manufacturers like ZhongBo that provide modular variations for specific circuit requirements.

-

Material and Plating Quality: Opt for nickel or tin-plated copper for corrosion resistance and optimal current handling.

-

Scalability: Verify production flexibility for both low-volume prototypes and bulk manufacturing.

-

Global Support: Partner with suppliers who provide technical assistance and consistent logistics across regions.

These principles align with the direction of smart factory development and sustainable electrical design worldwide.

Building Smarter Electrical Infrastructure

The modern terminal block is no longer a passive part—it is the backbone of reliable power and data connectivity. As automation, renewable energy, and industrial IoT expand, manufacturers like ZhongBo are bridging performance, compliance, and scalability with globally certified terminal block systems.

To learn more about ZhongBo’s engineering expertise and explore OEM collaboration, visit our homepage or get in touch via Contact Us for tailored solutions.