Optimizing Control Panel Efficiency: Insights on Terminal Blocks for PLC Wiring

Programmable Logic Controllers (PLCs) are the heart of automation systems, coordinating sensors, relays, and actuators across production lines.

Yet, one critical factor often overlooked in control design is the quality of the wiring interface.

Reliable terminal blocks for PLC wiring ensure stable signal transmission, simplify maintenance, and safeguard system uptime — key parameters for any industrial automation engineer.

The Role of Terminal Blocks in PLC Connectivity

In every automation cabinet, PLC terminals serve as connection hubs between field devices and controller input/output modules.

Their design directly influences wiring density, error rate, and long-term electrical reliability.

High-performance terminal blocks offer:

-

Consistent contact pressure via screw or spring clamps

-

Secure insulation barriers for low-voltage signal isolation

-

Compact modular profiles that fit tight PLC racks

-

Label and testing ports enabling faster commissioning

These features collectively reduce downtime and wiring complexity, supporting efficient plant maintenance cycles.

Engineering Design Principles for PLC Wiring Terminals

Modern PLC wiring systems demand precision-controlled mechanical and electrical interfaces.

Key design parameters include:

| Engineering Factor | Function | Recommended Standard |

|---|---|---|

| Pitch spacing | Determines wire density | 3.5mm / 5.08mm for control I/O |

| Contact material | Ensures conductivity | Nickel-plated brass or phosphor bronze |

| Insulation | Prevents signal interference | UL94 V-0 PA66 housing |

| Mounting method | Panel / DIN rail adaptability | IEC 60715 compatible |

| Voltage rating | Matches PLC I/O signals | 300V–600V depending on pitch |

Together, these specifications ensure robust, noise-resistant, and serviceable wiring for PLC-based automation systems.

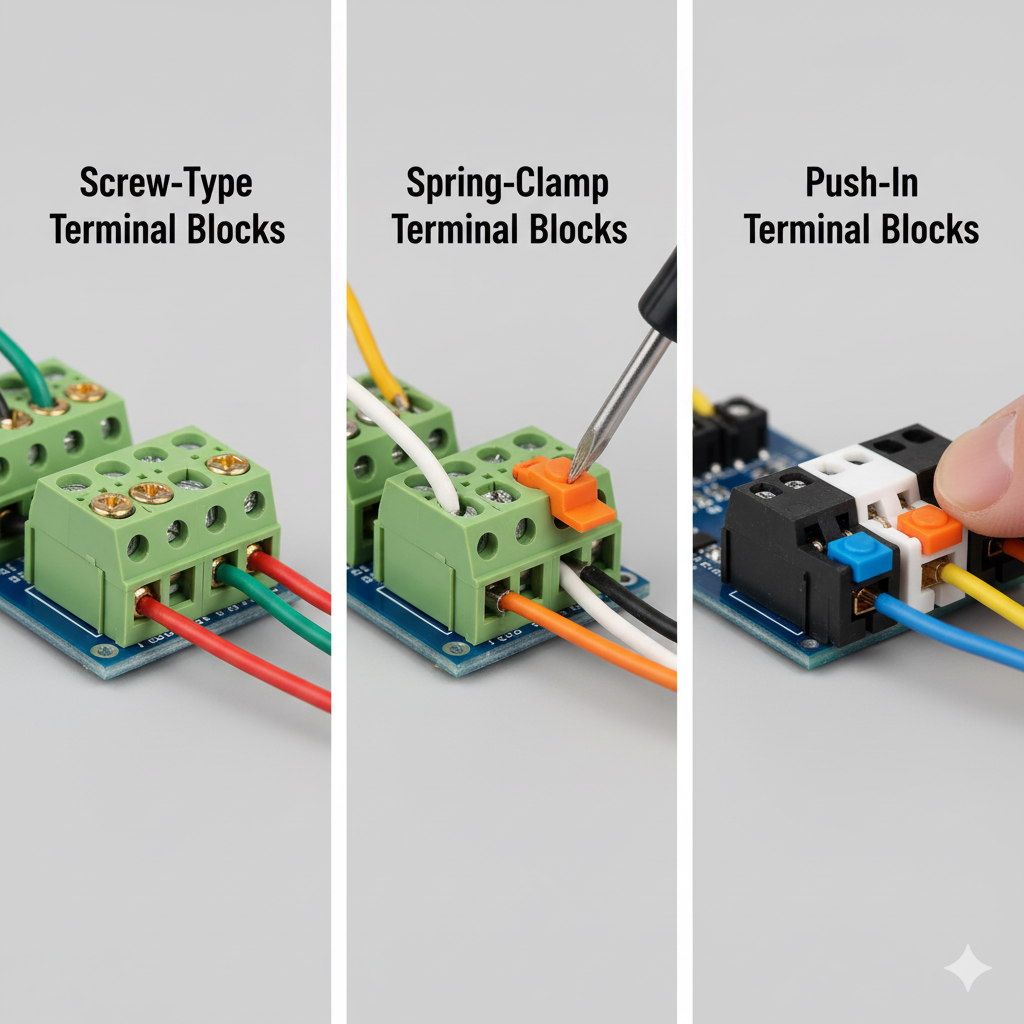

Comparing Wiring Technologies: Screw vs. Spring Clamp

| Parameter | Screw Type Terminal | Spring Clamp Terminal |

|---|---|---|

| Connection security | High torque retention | Self-adjusting elastic force |

| Installation speed | Moderate | Up to 50% faster |

| Maintenance | Requires periodic re-torque | Maintenance-free |

| Environment | Heavy vibration and load | Compact, frequent service |

| Use case | Motor control, high-current PLCs | Signal wiring and sensor arrays |

Both designs remain widely adopted. Screw-type terminals are favored in power-intensive PLC racks, while spring clamps excel in high-frequency maintenance zones such as packaging or assembly automation lines.

Key Advantages in Modern PLC Wiring Systems

-

Noise Suppression and Signal Stability

Advanced insulation design minimizes EMI and crosstalk between digital and analog I/O lines. -

Space Efficiency for Compact Cabinets

3.5mm–5.08mm pitch terminals maximize I/O density without compromising clarity or airflow. -

Maintenance-Friendly Layout

Push-in wiring and modular labeling simplify both installation and troubleshooting. -

Safety and Compliance

Tested under IEC 60947-7-1 and UL 1059, ensuring insulation integrity under industrial voltage stress. -

Custom OEM Options

Available in pluggable or multi-tier configurations for layered PLC assemblies.

Practical Recommendations for Automation Engineers

To achieve optimal wiring performance, PLC designers should consider:

-

Use color-coded terminal blocks to visually separate power, signal, and ground circuits.

-

Select modular types with plug-and-socket interfaces for modular PLC upgrades.

-

Apply shielded cables with proper grounding at terminal points to suppress noise.

-

Maintain minimum 10mm clearance between high-voltage and signal terminals.

-

Choose suppliers that provide CAD drawings, datasheets, and torque certification for compliance validation.

Integrating these design strategies ensures long-term system reliability while reducing installation labor.

Common Questions from Control System Integrators

Q1: What pitch is ideal for compact PLC panels?

A: 3.5mm or 5.08mm pitch is optimal for high-density control cabinets.

Q2: Can terminal blocks handle analog and digital signals simultaneously?

A: Yes. Dual-channel and multi-tier terminal designs separate voltage zones to minimize interference.

Q3: Are pluggable terminals recommended for field maintenance?

A: Yes. They enable quick module swaps without rewiring, ideal for modular PLC racks.

Q4: How often should screw-type terminals be serviced?

A: Annual torque verification is recommended in vibration-prone environments.

Advancing Automation Through Reliable Connection Engineering

The evolution of terminal blocks for PLC wiring represents more than convenience — it’s a shift toward modular, maintainable, and safer automation infrastructure.

As control systems grow smarter, connection reliability becomes the foundation of digital efficiency.

Zhongbo continues to deliver certified terminal block solutions for PLCs and control panels, integrating precise molding, UL-rated materials, and OEM customization to meet diverse industrial automation needs.

For technical consultation or OEM inquiries, visit our homepage or contact us.