Tailored for Industry Demands: How OEM AC Terminal Blocks Fit Energy, Transport, and Automation

Why OEM Matters in Critical Industries

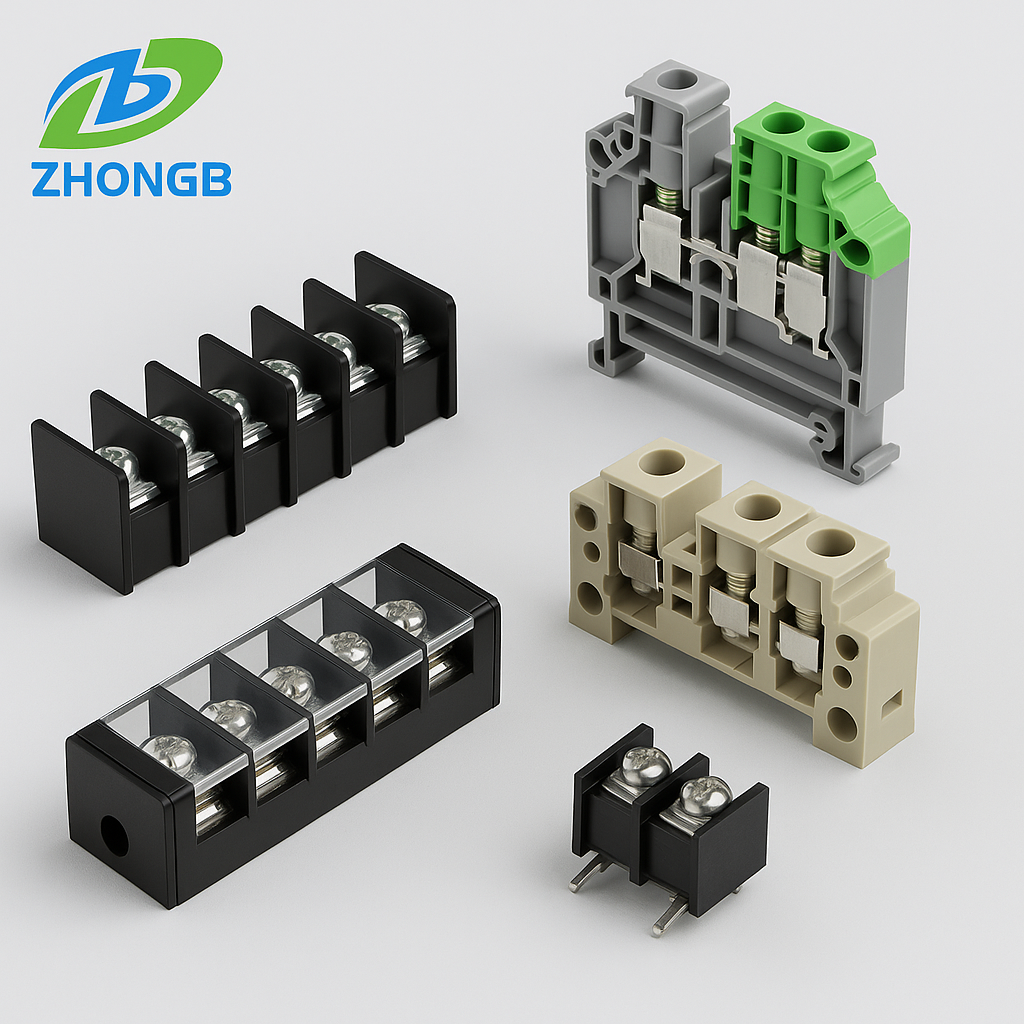

Electrical connectors may look like small details, but in high-stakes industries, their performance can determine whether systems run safely for decades or fail within months. Standard terminal blocks provide baseline functionality, but OEM AC terminal blocks allow manufacturers to address unique challenges of different industries. This means adapting not only the dimensions and materials, but also the safety standards, compliance requirements, and long-term durability that each project demands.

Energy Systems: Managing Heat and Heavy Loads

Renewable energy projects such as solar and wind place continuous stress on electrical systems. Current levels surge during peak production and drop at night, creating heat cycles that strain every connection point. Standard connectors often degrade under these fluctuations.

OEM terminal blocks for energy systems integrate:

-

Reinforced insulation and creepage distances to prevent arc faults.

-

Heat-dissipating metal alloys that withstand constant load shifts.

-

Mounting flexibility to fit both inverter cabinets and grid-side panels.

-

IEC-compliant spacing (IEC) ensuring safety in high-voltage applications.

With OEM customization, renewable projects achieve stable long-term operation, reducing both downtime and costly maintenance.

Transport Networks: Resisting Vibration and Stress

In railway and metro systems, connectors endure vibration equivalent to thousands of mechanical stress cycles every day. A slightly loose connection could interrupt signaling or even compromise passenger safety.

OEM AC terminal blocks for transport applications are engineered with:

-

Vibration-proof clamping that resists loosening under constant movement.

-

Corrosion-resistant alloys to survive exposure to humidity, dust, and temperature shifts.

-

Compact housing designs tailored for signaling and control panels with limited space.

-

Extended life testing, simulating years of service before deployment.

This ensures safety-critical networks run with consistent reliability, avoiding unexpected failures.

Industrial Automation: Space and Safety in Crowded Cabinets

Automation systems face a different challenge: limited panel space with increasingly complex wiring. High-density layouts often increase risks of overheating or wiring errors if not carefully managed.

OEM AC terminal blocks in automation focus on:

-

Compact footprints that maximize wiring density while maintaining insulation clearances.

-

Color-coded and OEM-labeled designs that speed up troubleshooting and reduce error rates.

-

Scalable production options—from small prototypes for pilot lines to full mass supply for global automation projects.

-

UL certification (UL) embedded in the design phase for international market access.

By balancing space efficiency with safety, OEM connectors give automation systems the flexibility to expand without sacrificing reliability.

OEM vs Standard Terminal Blocks

| Factor | Standard AC Block | OEM AC Terminal Block |

|---|---|---|

| Design Fit | Generic sizing | Tailored for cabinets, inverters, and panels |

| Durability | Basic materials | Reinforced for vibration, heat, or harsh climates |

| Compliance | General CE mark | Integrated IEC/UL/ISO certifications |

| Brand Integration | None | Custom labeling and OEM packaging |

| Lifecycle Value | Short-term fit | Lower downtime and long-term savings |

This makes OEM solutions a strategic investment rather than a simple purchase.

Building Trust Through OEM Partnerships

In industries where downtime can cost millions, reliability is not optional. OEM AC terminal blocks deliver assurance by embedding compliance, durability, and adaptability into every component.

At ZhongBo, OEM solutions are not a one-off customization—they are part of a structured process that begins with prototyping and extends through compliance certification and mass production. With scalable supply chains and rigorous testing, ZhongBo ensures products perform not only in the factory but in the toughest real-world environments.

For tailored OEM solutions in energy, transport, or automation, explore our homepage or connect with us through the contact page.