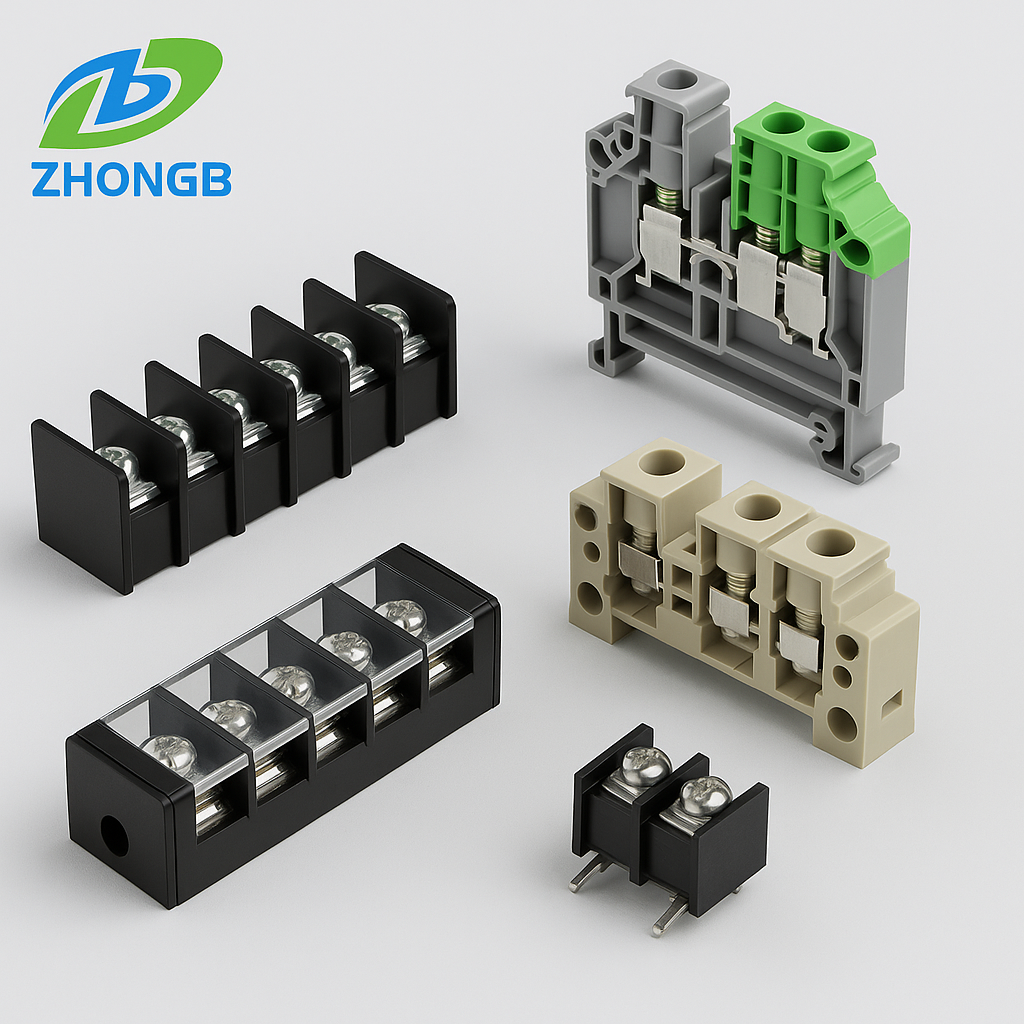

Custom Electrical Connectors: Tailored Designs for Demanding Systems

Why Customization Matters in Electrical Connectors

In modern electrical systems, reliability often depends on the smallest details. Standard connectors are convenient, but they are not always optimized for high current, environmental stress, or unique system layouts. Using the wrong connector can lead to overheating, voltage drops, or even full system downtime. Custom electrical connectors solve these challenges by aligning dimensions, materials, and performance with specific project needs.

Five Advantages of Custom Electrical Connectors

Custom connectors are designed with purpose, delivering improvements that generic models cannot:

-

Safety – Reinforced insulation and secure locking mechanisms minimize failure risks.

-

Compatibility – Tailored dimensions ensure seamless fit with cabinets, machinery, and equipment.

-

Durability – Built with materials that resist heat, vibration, and environmental stress.

-

Efficiency – Streamlined designs reduce installation complexity and wiring errors.

-

Compliance – Certification-ready designs meet ISO, CE, and UL standards.

These advantages make custom connectors essential in projects where reliability is non-negotiable.

Where Custom Connectors Deliver Value

Industries increasingly rely on custom electrical connectors to solve real-world challenges:

-

Automation Systems – High-density connectors save space and simplify wiring in control cabinets.

-

Renewable Energy – Specialized connectors handle high current in solar inverters and wind converters.

-

Transportation – Rugged, vibration-resistant designs ensure stability in rail and automotive systems.

-

Telecommunications – Clear, shielded connectors reduce interference in signal control panels.

-

Special Equipment – Medical devices and defense systems require precision-engineered connectors for mission-critical safety.

By addressing these environments, custom connectors improve both performance and operational continuity.

Custom vs. Generic Connectors: The Value Points

| Aspect | Generic Connector | Custom Electrical Connector |

|---|---|---|

| Fit & Dimensions | Standard only | Tailored to exact system needs |

| Material Options | Basic plastics/metals | High-grade insulation, reinforced alloys |

| Performance | Moderate | Optimized for high current or vibration resistance |

| Compliance | General CE only | ISO/CE/UL verified per project demand |

| Scalability | Limited models | OEM-ready for prototypes to bulk production |

This shows how customization adds measurable value to demanding projects.

Common Questions About Custom Connectors

-

“How long does customization take?”

Prototyping is completed in short cycles, with scalable production ready once designs pass validation. -

“Can small orders be customized?”

Yes, pilot runs are possible before moving to large-scale production. -

“How are connectors tested?”

Each custom connector undergoes rigorous testing for conductivity, thermal resistance, and dielectric strength. -

“Will customized connectors meet certification requirements?”

At ZhongBo, all custom electrical connectors are designed and validated under ISO9001, CE, and UL standards.

Turning Customization into Long-Term Reliability

Custom electrical connectors provide more than tailored dimensions—they build reliability into entire systems. With OEM flexibility, scalable production, and strict certification, ZhongBo ensures that every connector is engineered to perform under the toughest conditions.

To learn more about tailored solutions for electrical connectors, visit our homepage or contact us directly through the contact page.