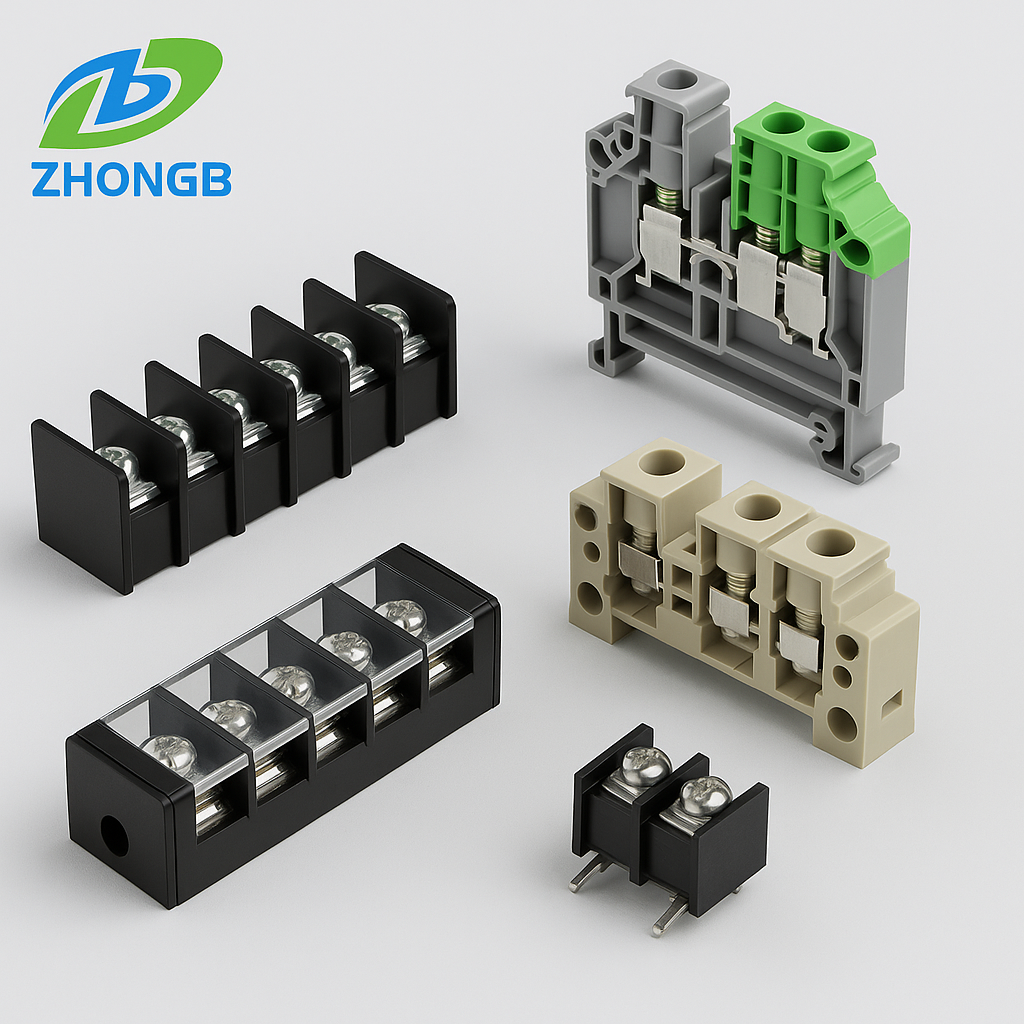

AC Terminal Block Manufacturer: Powering Reliable Connections in AC Systems

Why AC Terminal Blocks Are Different

AC systems require stability and safety under constant alternating current flow. Unlike DC, AC current involves continuous polarity shifts, which can generate heat and stress at connection points. AC terminal blocks are designed with higher insulation, precise spacing, and durable materials to withstand these conditions. A professional manufacturer ensures that each component can handle the challenges of real-world AC distribution.

Manufacturer’s Role in AC System Reliability

Producing AC terminal blocks involves more than molding plastic and metal. At ZhongBo, the factory integrates:

-

Material Engineering – Flame-retardant insulation and corrosion-resistant metals for long service life.

-

Precision Assembly – CNC machining ensures screws and clamps hold wires securely, even under vibration.

-

Thermal Management – Designs optimized to reduce heat build-up from alternating loads.

-

Certifications – CE, IEC standards compliance, and UL validation for international acceptance.

These factors allow AC terminal blocks to deliver stable performance in high-demand environments.

Industrial Applications of AC Terminal Blocks

AC terminal blocks are widely used in industries where alternating current is the backbone of operation:

-

Power Distribution Panels – Safe, modular connections in building and grid systems.

-

Industrial Machinery – Secure wiring for motors, pumps, and production lines.

-

Renewable Energy – Reliable connections in solar inverters and wind converters where AC conversion is key.

-

Transportation – Railway and automotive AC systems requiring vibration-resistant blocks.

-

Construction Projects – Wiring infrastructure for high-rise and commercial facilities.

In all these areas, quality AC terminal blocks reduce risks and improve long-term efficiency.

Key Features That Define AC Terminal Blocks

| Feature | Why It Matters | Manufacturer Advantage |

|---|---|---|

| Insulation Strength | Handles alternating polarity safely | High-grade, flame-retardant materials |

| Heat Resistance | Prevents overheating under heavy AC loads | Optimized thermal design and tested alloys |

| Secure Clamping | Reduces risk of wire loosening | Precision-engineered screws and clamps |

| Durability | Withstands vibration and stress | Reinforced housings for industrial use |

| Compliance | Ensures global market acceptance | ISO/CE/UL certifications applied across production |

This table shows how AC-specific features go beyond general-purpose terminal blocks.

Common Questions About AC Terminal Block Manufacturers

-

“What current ranges do AC terminal blocks support?”

Models are available for low to high current, with reinforced insulation for heavy-duty applications. -

“Can OEM customization be applied to AC blocks?”

Yes. Options include screw size, barrier design, and materials tailored for project-specific conditions. -

“How is heat management ensured?”

Products are tested under simulated AC load conditions to verify conductivity and thermal resistance. -

“Are certifications included for export?”

At ZhongBo, all AC terminal blocks are validated under ISO9001, CE, and UL certification to meet international compliance.

Trust in Manufacturing Strength

AC terminal blocks are not interchangeable with generic connectors—they are engineered for the unique challenges of alternating current. With strong design capabilities, rigorous testing, and scalable supply, ZhongBo ensures that every AC terminal block contributes to safe, reliable, and efficient systems.

To explore certified AC solutions, visit our homepage or connect with us through the contact page.