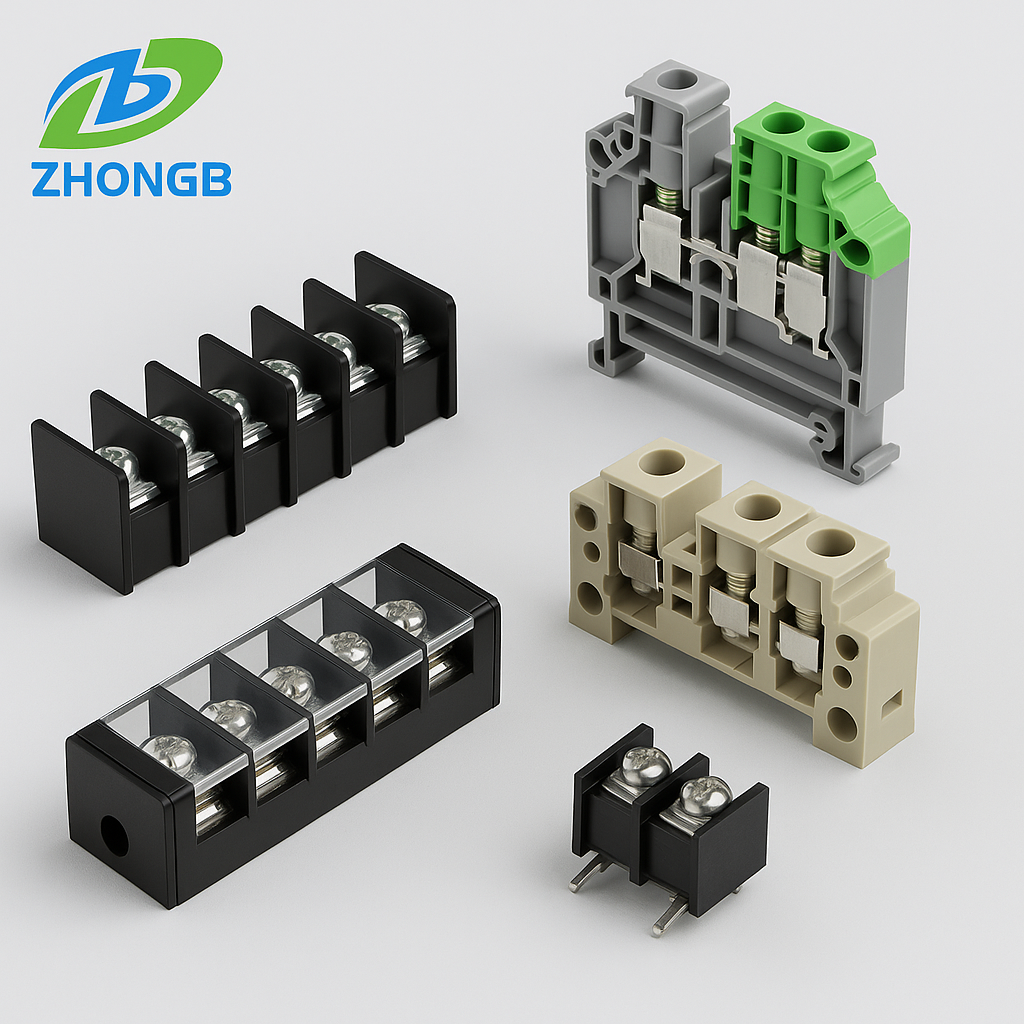

Custom AC Terminal Block Solutions That Fit Safety, Scale, and Industry Needs

Why Customization Is Essential

In electrical systems, alternating current places continuous stress on every connection point. A generic terminal block may be sufficient in low-demand setups, but when exposed to heavy loads, vibration, or outdoor conditions, its limitations quickly surface. Custom AC terminal blocks address these risks by aligning design and materials with the real environment where they are installed.

The Core Value of Custom AC Terminal Blocks

Customization is not about minor adjustments; it is about building reliability into the product from the start. Through tailored insulation, geometry, and clamping design, custom blocks ensure long-term safety where standard models cannot. The main values are:

-

Safety first – Higher insulation ratings prevent arc faults and overheating.

-

Application fit – Dimensions and mounting options are adapted to tight or complex panels.

-

Durability – Materials are selected to resist vibration, dust, or moisture depending on the site.

Each factor translates into fewer failures and lower lifecycle costs.

Industry Environments That Require Customization

Different industries impose unique technical and environmental challenges. Custom AC terminal blocks adapt to these conditions, turning potential risks into reliable performance:

| Industry | Key Challenges | Customization Focus |

|---|---|---|

| Energy Systems | Continuous load shifts, high operating temps | Reinforced insulation, heat-dissipating structures |

| Transportation | Constant vibration, mechanical stress | Vibration-proof clamps, secure screw mechanisms |

| Industrial Automation | Limited cabinet space, wiring density | Compact designs, optimized safety clearances |

| Construction Projects | Large distribution boards, complex wiring | Modular blocks, color coding, easy maintenance |

| Outdoor/Harsh Environments | UV, dust, moisture, climate extremes | Weather-resistant housings, corrosion-proof materials |

This comparison shows how customization ensures each terminal block is not only compliant but also perfectly aligned with real-world demands.

Why Customization Creates Long-Term Value

When companies choose customization, they are investing in more than a product—they are investing in operational assurance. Customized blocks:

-

Reduce downtime by eliminating common failure points.

-

Shorten maintenance cycles with clearer wiring and labeling.

-

Ensure compliance with ISO, CE, and UL standards from the prototype stage.

This makes customization not only a technical solution but also a strategic decision for long-term efficiency.

How Customization Supports Global Compliance

For companies exporting electrical equipment, compliance is as important as performance. A terminal block that performs well locally may still fail to meet the regulatory requirements of another market. Custom AC terminal blocks solve this problem by being designed with international certifications in mind from the very beginning.

Tailored models can:

-

Integrate IEC spacing rules for safe clearances in high-voltage projects.

-

Use materials already approved under UL flammability ratings, ensuring acceptance in North America.

-

Align with CE marking for Europe, making cross-border deployment easier.

By embedding compliance into the customization process, manufacturers like ZhongBo reduce certification delays and give customers confidence that their systems will meet both technical and legal standards wherever they are installed.

Reliability Built for Real Projects

In modern AC systems, safety and adaptability cannot be optional. Custom AC terminal blocks allow projects to combine compliance, durability, and fit-for-purpose design in one solution.

At ZhongBo, every custom block is developed with specific industries in mind, validated through rigorous testing, and produced at scale to support both urgent and long-term supply needs. This ensures that what starts as a tailored design becomes a reliable component trusted in real-world operations.

To explore tailored AC solutions for your next project, visit our homepage or connect with us through the contact page.