Powering Modern Factories: AC Terminal Blocks in Industrial Automation

Reliable Wiring as the Backbone of Automation

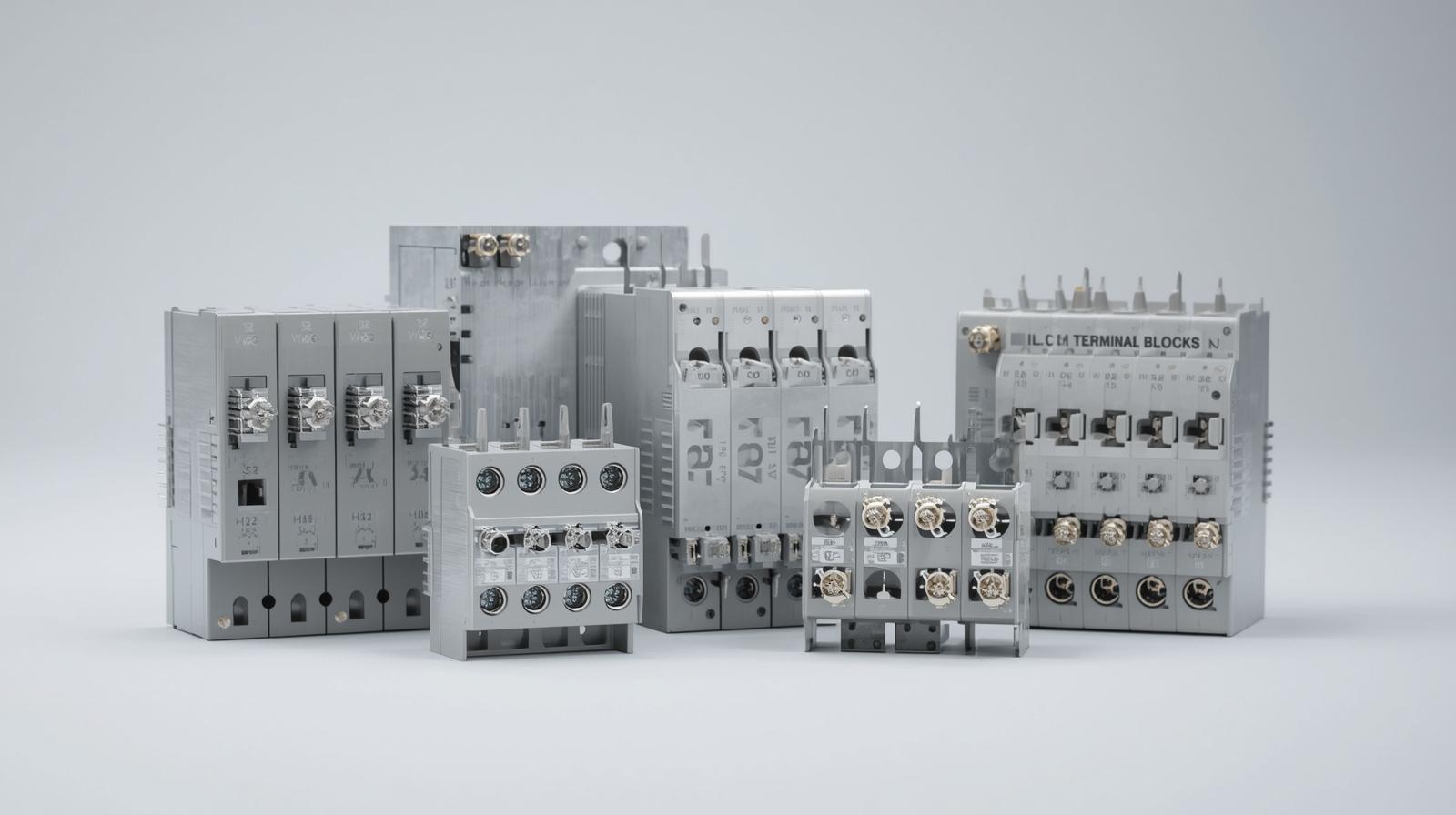

Modern factories are increasingly digital, operating with robotics, PLCs, IoT sensors, and automated machinery. Each of these systems depends on safe and stable wiring to function without interruption. AC terminal blocks are not just connectors; they are the backbone of industrial automation, ensuring current distribution remains safe, efficient, and compliant even under heavy loads and long operating cycles.

The International Society of Automation (ISA) reports that wiring failures contribute to nearly half of unplanned downtime in manufacturing environments (ISA), proving the importance of choosing durable, OEM-grade components.

The Challenges of Factory Wiring—and OEM Solutions

-

Tight Control Cabinets

Automation panels often pack dozens of connections into compact spaces. ZhongBo’s slim modular terminals help engineers optimize cabinet layouts while still meeting insulation and safety standards. -

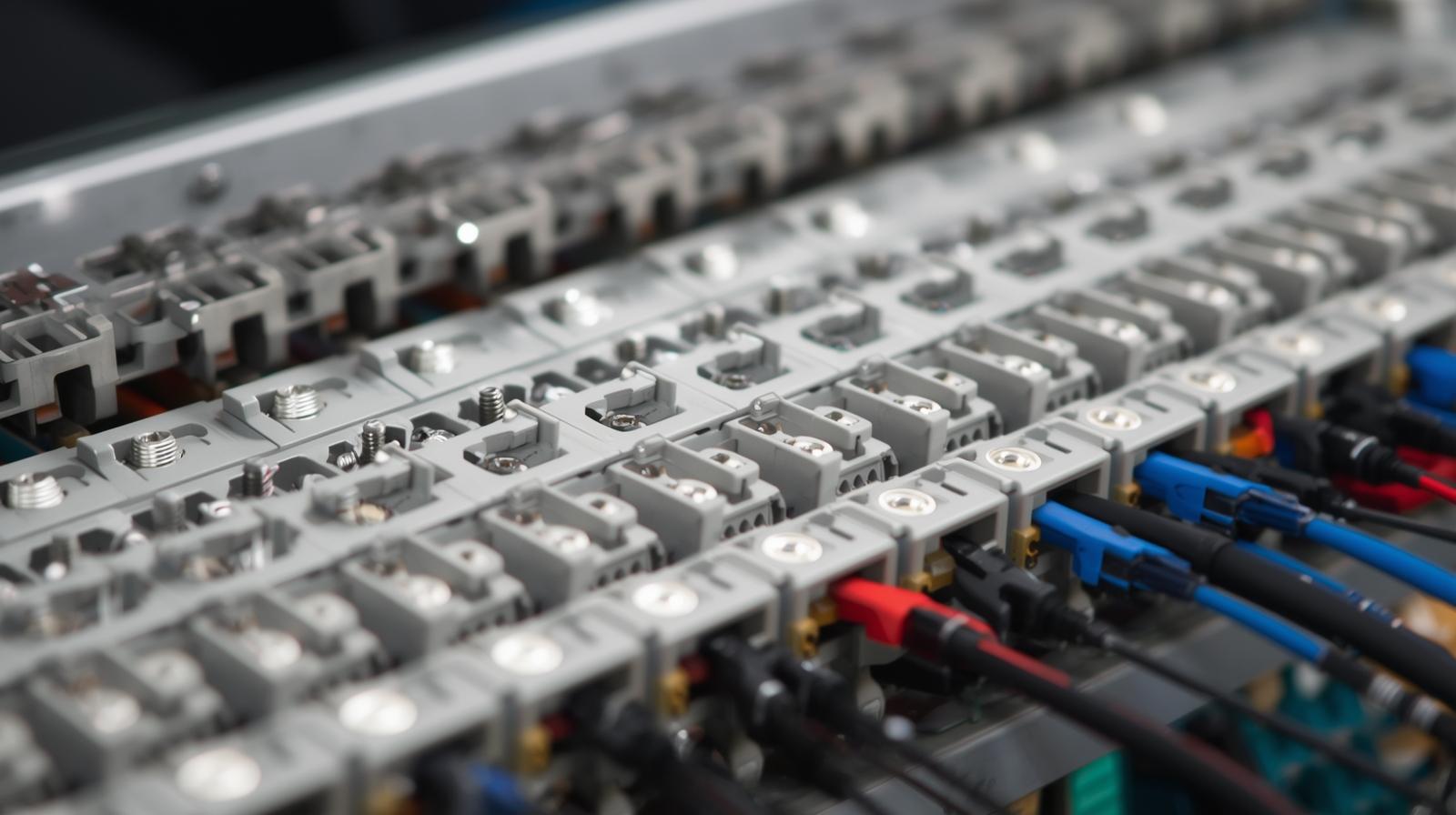

High Vibration from Heavy Machinery

Motors, presses, and conveyors generate constant vibration. OEM spring clamp and reinforced screw designs prevent loosening and maintain conductivity under these conditions. -

Maintenance Efficiency

With production running 24/7, downtime is costly. Quick-release and color-coded designs reduce technician error and accelerate troubleshooting. -

Safety and Compliance

Factories working in global supply chains must adhere to IEC, CE, and UL certifications, ensuring uniform quality across installations.

Industry Applications: Where AC Terminal Blocks Deliver Value

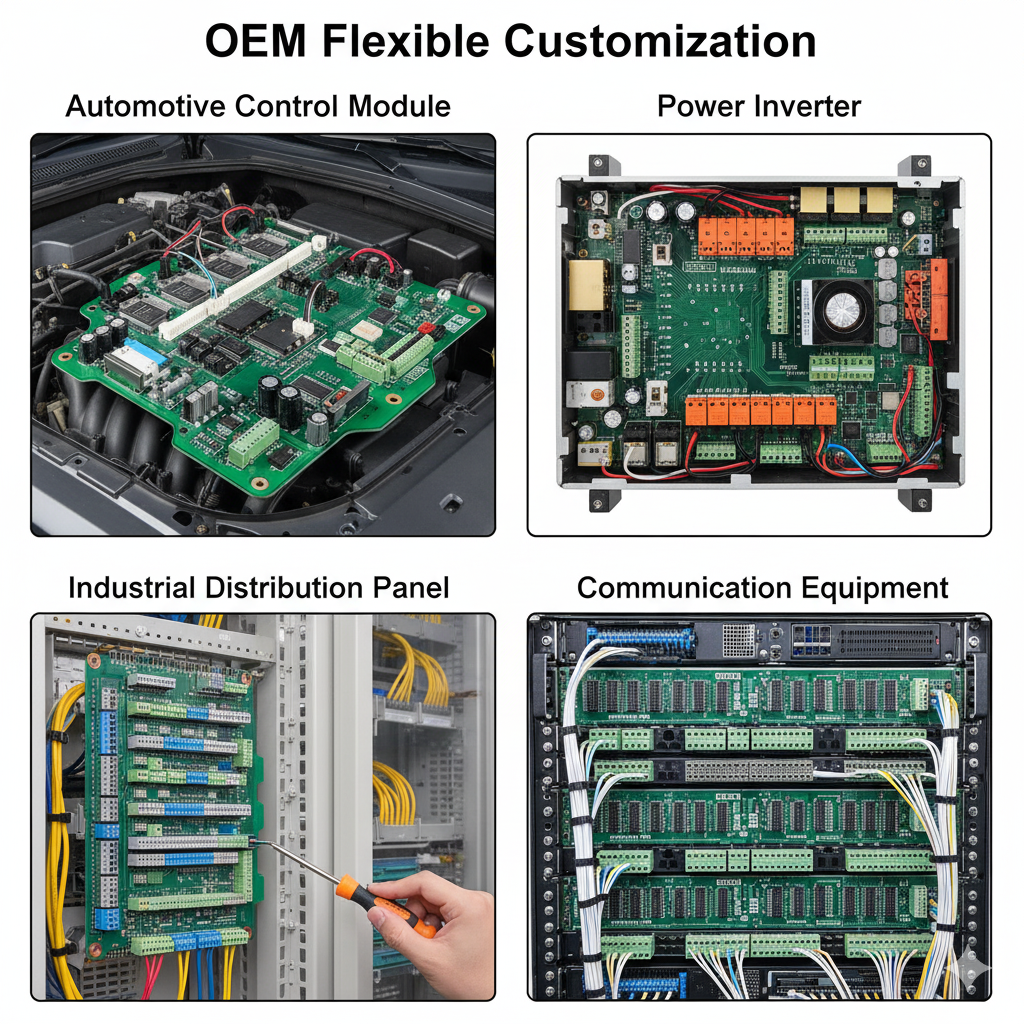

AC terminal blocks play a role across multiple industrial environments, each with its own technical requirements:

-

Robotics Assembly Lines – High-density wiring demands compact plug-in blocks that minimize cabinet size while supporting precise control circuits.

-

Motor Control Centers (MCCs) – High-current screw-type blocks ensure reliable power distribution for motors under heavy loads.

-

Automated Packaging Equipment – Vibration-resistant terminals reduce unexpected stoppages caused by wiring failures.

-

HVAC Systems in Factories – Modular AC terminal blocks simplify wiring for ventilation and cooling systems, critical for energy efficiency.

-

Smart Factory Integration – Spring clamp connectors provide quick installation for IoT sensors and PLC devices, supporting Industry 4.0 transitions.

These applications show how customization ensures each factory system runs safely and efficiently, preventing costly downtime.

Factory Needs vs. ZhongBo OEM Solutions

| Application Area | Key Challenge | OEM Terminal Block Solution |

|---|---|---|

| Robotics Assembly Lines | Dense wiring in small spaces | Slim modular plug-in terminals |

| Motor Control Centers | High current loads | Heat-resistant screw terminals |

| Packaging Equipment | Constant vibration | Anti-vibration spring clamp designs |

| HVAC Systems | Complex wiring & maintenance | Modular blocks with quick identification |

| Smart Factory Systems | IoT & PLC integration | Compact spring clamp connectors |

Q&A: Addressing Buyer Concerns

Q1: Can AC terminal blocks reduce downtime in automation projects?

Yes. Modular and quick-release designs allow for faster replacements and wiring verification, cutting downtime by up to 25%.

Q2: How do OEM designs adapt to high-load equipment?

ZhongBo uses reinforced insulation, heat-resistant alloys, and certified testing to ensure performance in motor-heavy systems.

Q3: Are these blocks suitable for global factory installations?

All products are certified to IEC, CE, and UL standards, ensuring cross-border compliance for multinational projects.

Building the Factory of the Future with ZhongBo

As industrial automation expands, reliable wiring becomes a competitive advantage. AC terminal blocks, when designed with OEM flexibility, allow factories to scale operations, integrate new technologies, and maintain safety without interruption.

At ZhongBo, we bring together CNC machining, automated production lines, and over 50 advanced testing procedures to guarantee that every block is ready for demanding industrial environments. By combining engineering precision, compliance, and customization, ZhongBo delivers more than connectors—we provide the backbone of modern automation systems.

For tailored industrial solutions, explore our homepage or contact us with your project requirements through our contact page.