PCB terminal block technology isn't standing still. Staying ahead of these trends empowers designers to create next-generation electronics:

-

Miniaturization & Higher Density:

-

Demand for smaller devices drives finer pitches (< 3.5mm) and lower-profile blocks. SMT adoption increases, enabling denser layouts and automated assembly. Expect more creative multi-level stacking solutions.

-

-

Enhanced Push-In Technology:

-

Spring cage designs continue to evolve for easier tool-less operation (both insertionandrelease), wider wire gauge acceptance within the same footprint, and even higher vibration resistance.

-

-

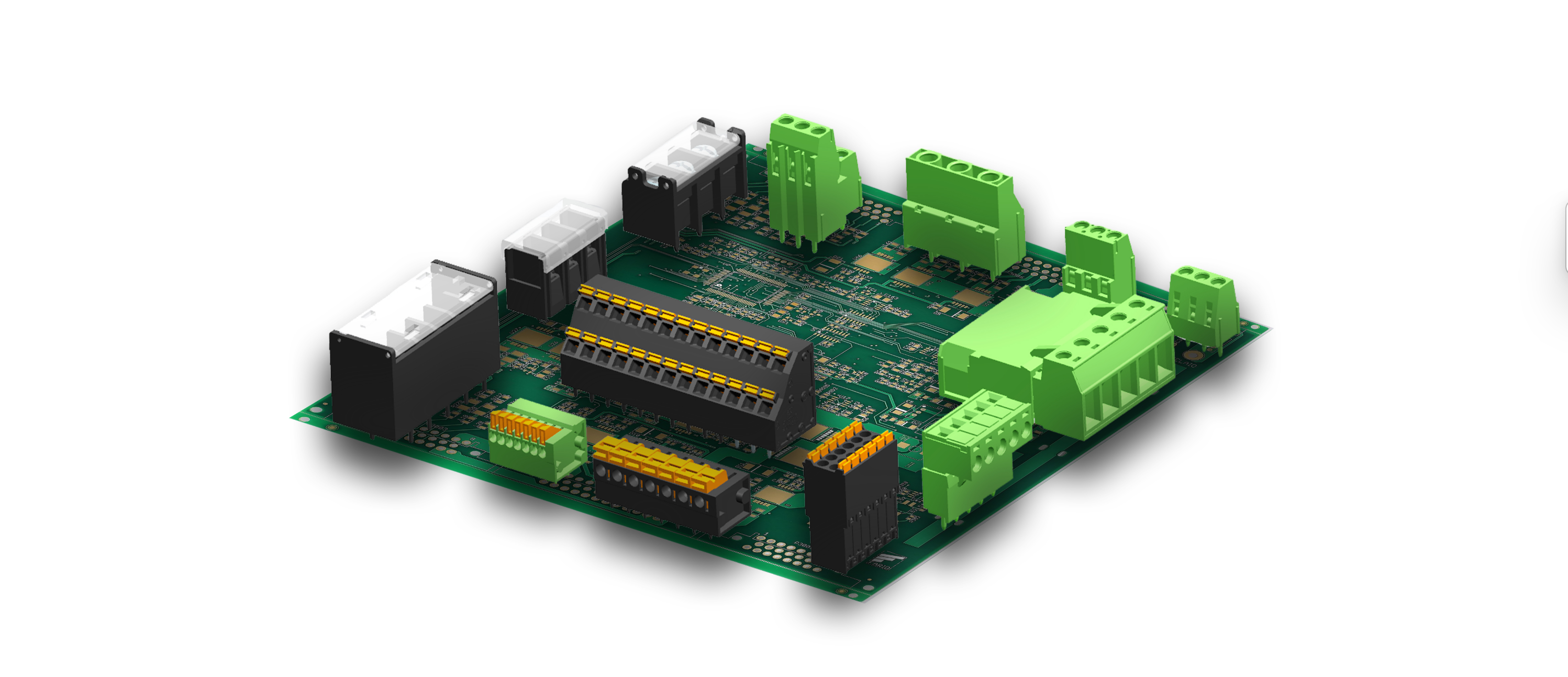

Integrated Functionality:

-

Terminal blocks are becoming smarter connection points:

-

Integrated Fusing:Combining terminal blocks with fuse holders on the PCB saves space and simplifies safety.

-

Integrated Shunts/Jumpers:Built-in options for easy circuit configuration without separate jumper wires.

-

Integrated LED Indicators:Visual status (power, signal) directly at the connection point.

-

Integrated Test Points:Facilitating easier circuit debugging and maintenance.

-

-

-

Focus on High-Speed Data:

-

As industrial IoT and automation require more data, terminal blocks designed for reliable signal integrity at higher frequencies (e.g., for Ethernet, USB, or fieldbus connections) are emerging, incorporating shielding and controlled impedance features.

-

-

Material Science Advances:

-

Development of new, high-performance polymers offering superior:

-

Flame retardancy (UL94 V-0 remains critical).

-

Thermal stability for lead-free soldering and higher ambient temperatures.

-

Resistance to harsher chemicals and environmental stressors.

-

Improved mechanical strength in smaller packages.

-

-

-

Sustainability & Circular Design:

-

Increased focus on RoHS3 compliance, halogen-free materials, and designs facilitating easier disassembly and material recycling at end-of-life.

-

Designer Takeaway:Collaborate closely with innovative terminal block manufacturers early in the design process. Leverage their expertise in these emerging trends to achieve smaller, smarter, more reliable, and more sustainable PCB assemblies. Ask about custom solutions for cutting-edge applications.