From Ports to Power: Why Ningbo Leads as a Global Terminal Block Export Hub

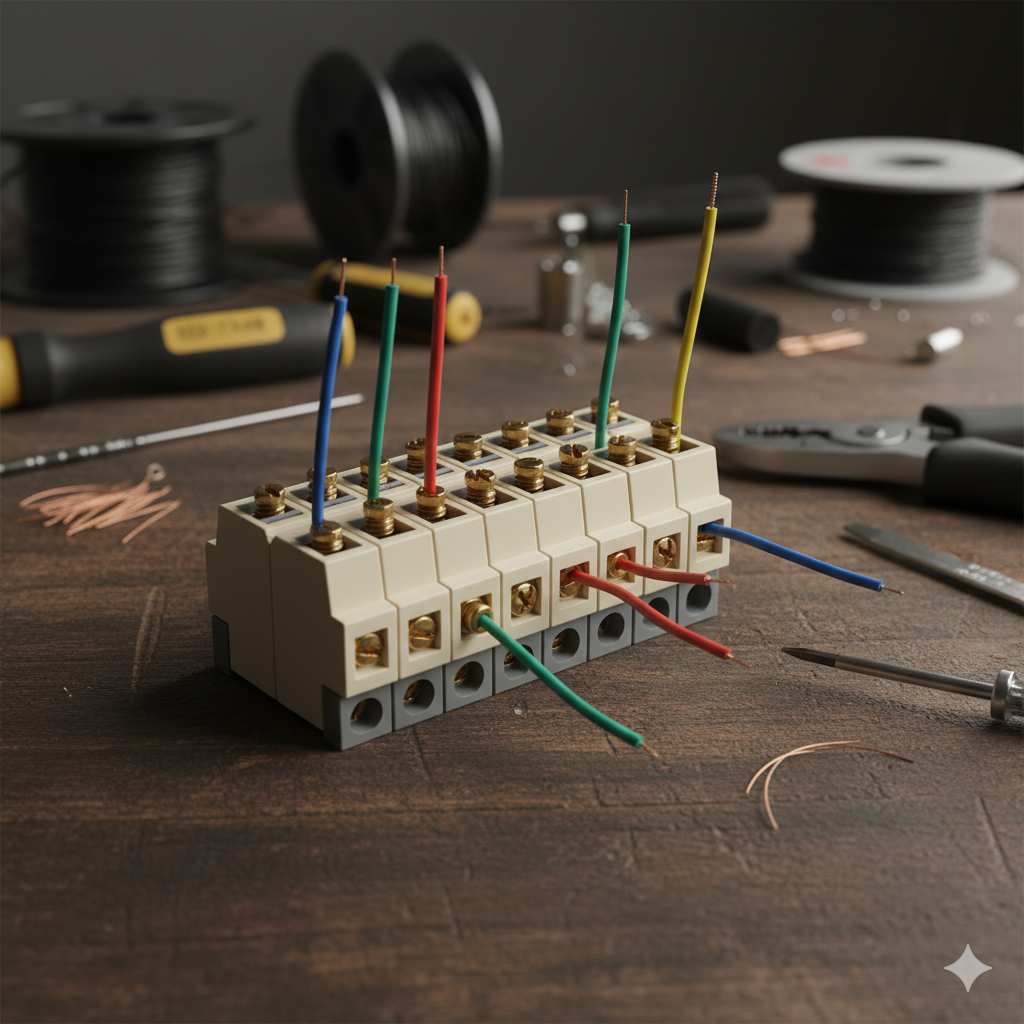

As one of China’s most dynamic industrial cities, Ningbo has long been recognized for its manufacturing depth and world-class port logistics.

Today, it is also a major global base for terminal block exports, serving automation, energy, and industrial wiring systems in more than 80 countries.

Behind every shipment leaving the Port of Ningbo lies a network of specialized factories — combining engineering precision, certification compliance, and OEM customization — that make the city a trusted partner for global electrical component buyers.

Ningbo’s Manufacturing Advantage in Electrical Components

Ningbo’s strength as an export center is built on its integrated industrial ecosystem.

Over the past decade, the city has attracted thousands of suppliers and tooling specialists focused on high-precision plastic and metal components — the foundation for terminal block production.

Key advantages include:

-

Clustered manufacturing — injection molding, stamping, plating, and assembly all within 20 km radius.

-

Certified facilities — UL, CE, ISO9001, and RoHS-compliant workshops supporting global exports.

-

Rapid logistics — proximity to Ningbo-Zhoushan Port, one of the world’s busiest export terminals.

-

Engineering synergy — collaboration between mold designers, electrical engineers, and export professionals.

This synergy allows Ningbo-based factories to produce high-quality, customizable terminal blocks with short lead times and competitive global pricing.

Engineering Quality Behind Ningbo’s Terminal Block Exports

Ningbo manufacturers combine traditional craftsmanship with digital precision. Each export-grade terminal block undergoes strict testing and certification processes.

| Design Parameter | Specification | Compliance Standard |

|---|---|---|

| Housing | UL94 V-0 PA66 / PBT | Flame-retardant and high insulation |

| Conductor | Tin-plated copper or brass | High conductivity and corrosion resistance |

| Voltage Rating | 300V–1000V | UL1059 / IEC60947 |

| Temperature Range | -40°C to +125°C | Continuous industrial-grade operation |

| Pitch Range | 2.54–10.16mm | PCB and modular wiring compatibility |

| Torque Test | Automated precision testing | Ensures mechanical stability |

By integrating automated torque inspection, dielectric testing, and 3D quality scanning, Ningbo exporters deliver products that meet or exceed the standards of European and North American markets.

Global Reach and Industry Applications

Ningbo’s terminal block exporters serve multiple industries that depend on reliable and standardized wiring solutions:

-

Automation & control panels – PLCs, sensors, and I/O distribution modules

-

Renewable energy – solar combiner boxes, inverters, and ESS cabinets

-

HVAC & building systems – power controllers and thermostatic circuits

-

Lighting and LED – PCB terminal blocks for driver modules

-

Transportation & EVs – onboard connectors for charging systems

With export certifications such as UL, CE, and TUV, Ningbo manufacturers provide products that integrate seamlessly into global supply chains without the need for re-certification.

Selecting Terminal Blocks Based on Export Application

Buyers sourcing from Ningbo should consider both application environment and electrical specification when selecting terminal blocks:

-

For industrial automation → choose spring-cage or screw terminals for vibration resistance and secure signal transmission.

-

For renewable energy systems → use high-voltage 1000V DC terminals with anti-tracking materials.

-

For HVAC or commercial installations → select modular pluggable terminals that allow easy wiring replacement.

-

For compact electronics → opt for miniature PCB terminals with 2.54mm to 5.08mm pitch spacing.

-

For power distribution systems → use barrier-type terminals capable of handling up to 150A current.

Matching the correct product ensures safety, reliability, and compliance in export markets.

Frequently Asked Questions

Q1: What certifications do Ningbo exporters usually hold?

A: UL, CE, TUV, and ISO9001 certifications are standard among leading factories.

Q2: Can Ningbo suppliers provide OEM customization?

A: Yes. Factories typically offer color, logo, and pitch customization for brand-specific designs.

Q3: What is the typical lead time for overseas shipments?

A: Standard production takes 15–25 days, with fast customs clearance through Ningbo Port.

Q4: Are Ningbo terminal blocks suitable for European and U.S. markets?

A: Yes. Products comply with IEC and UL standards, enabling direct export to EU and North America.

Connecting Global Industries Through Ningbo Engineering

From concept to cargo ship, Ningbo’s manufacturing ecosystem represents the strength of Asian engineering and supply reliability.

With certified facilities, rapid logistics, and proven export experience, Zhongbo continues to deliver terminal block solutions trusted by industrial and energy customers worldwide.

For technical specifications or OEM export cooperation, visit our homepage or contact us.