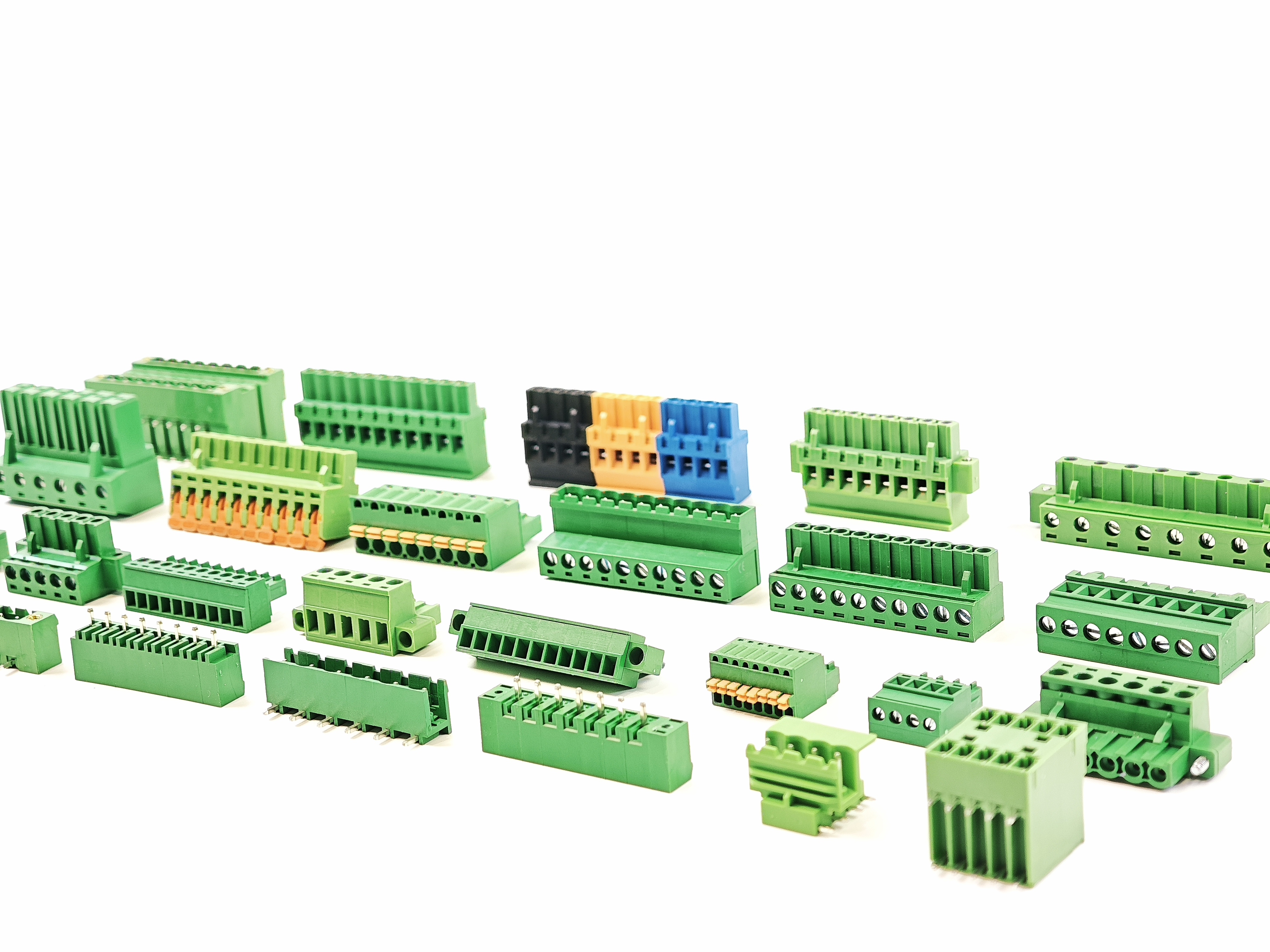

Industrial environments demand robustness and reliability. PCB terminal blocks are unsung heroes within PLCs, motor drives, sensors, and control panels. Here's why they're vital:

-

Vibration & Shock Resistance:

-

Machinery generates constant vibration. Spring cage terminals excel here, maintaining gas-tight connections without loosening. Screw terminals require careful torqueing and periodic checks.

-

-

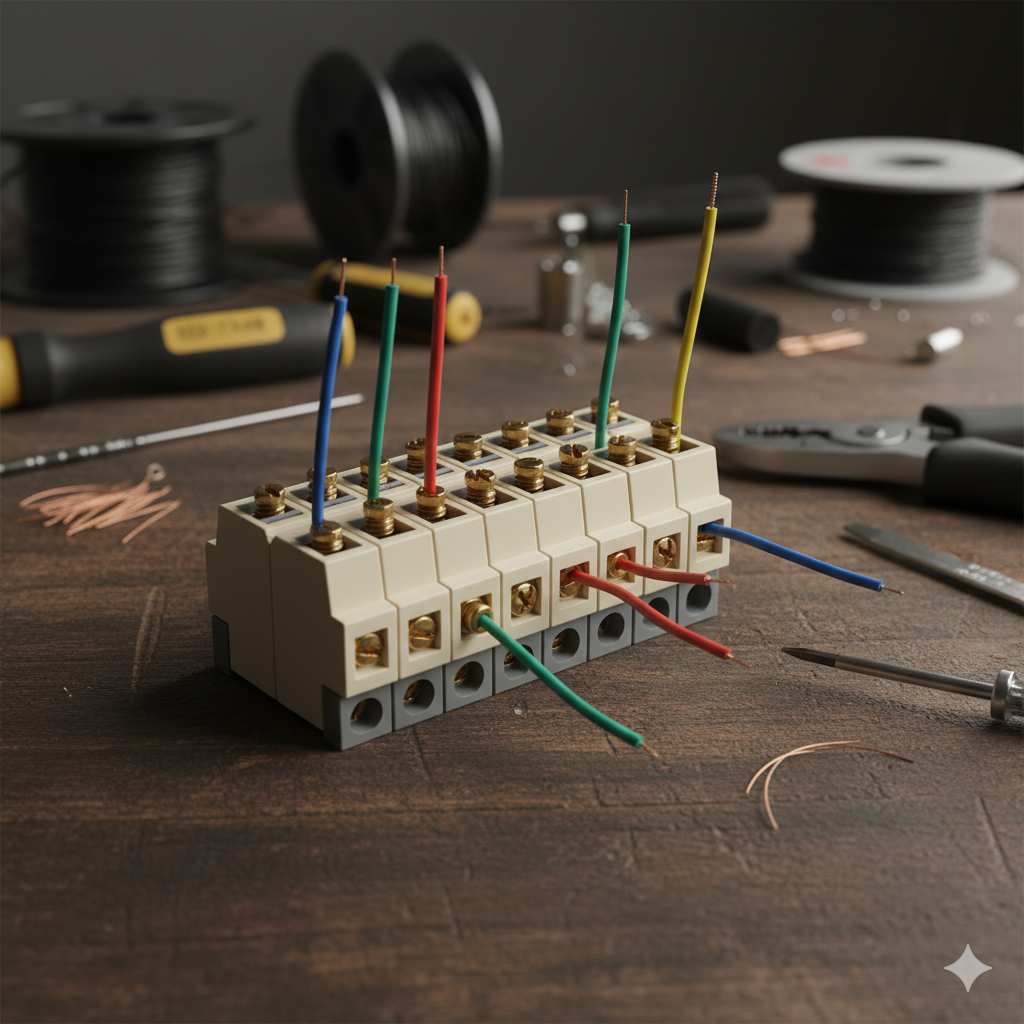

Secure Field Wiring:

-

Terminal blocks provide the essential, organized interface between internal PCBs and external field devices (sensors, actuators, power). They simplify wiring and prevent stray wires from stressing PCB solder joints.

-

-

Modularity & Serviceability:

-

Blocks enable modular design. Sections of a control system can be replaced or serviced by disconnecting wires at the terminal block, not desoldering. This minimizes downtime.

-

-

Signal & Power Distribution:

-

Multi-level blocks efficiently distribute power (24VDC, 120/230VAC) and low-voltage signal (sensor, comms) across the PCB, often incorporating test points or disconnects.

-

-

Environmental Protection:

-

Industrial settings involve dust, moisture, and temperature extremes. Look for blocks with:

-

High IP ratings (when used with appropriate housings/glands).

-

Wide operating temperature ranges (-40°C to +105°C+ common).

-

Materials resistant to oils, coolants, and cleaning chemicals (e.g., high-quality PA, PBT plastics).

-

-

Pluggable blocks allow pre-wired harnesses to be connected, speeding panel assembly and protecting connections.

-

Key Considerations for Industrial PCBs:

-

Certifications:UL/CSA/IEC (e.g., UL 1059, IEC 60947) and often specific approvals (e.g., cULus, ATEX for hazardous areas) are non-negotiable for safety and market access.

-

Visual Clarity:Clear labeling and potential color-coding (e.g., blue for signals, red for AC power) prevent critical wiring errors during installation and maintenance.

Choosing industrial-grade terminal blocks certified for harsh environments is an investment in system uptime and safety.